Here is a series of post detailing the restoration of a 1979 Honda CR250R "Red Rocket" I did

a few years ago. I always photographically document my restorations for the build books I

provide customers, or in this case, keep for myself.

Since quite a bit went into this process, I'll break it down into multiple installments. Comments

and suggestions are always welcome - I'm always on the look out for new ideas and methods.

You're going to see a lot Red in these posts, so all the Honda haters might want to avoid them.

Here are a couple of pictures of the bike right after I unloaded it from the truck. I bought it from

an EBay auction. The bike was 95% complete and looked OK from about 30 feet. Once you got

closer, things started going downhill. The bike had been subjected to what I like to call a "get it

ready to sell" restoration. New off brand tires, rattle can paint, lots of Armorall on the plastic and

rubber, etc. Still, a reasonably nice find and a great basis for a full on restoration.

I made the decision that this bike would be 100% OE Honda, no reproduction or aftermarket parts.

I knew that would make the resto very difficult, but well worth it if I could pull it off. I disassembled

the bike and divied everything into groups - engine, frame, suspension, wheels, etc.

First on the list was the engine. After breaking it down, I was thriled to find that it's original chrome

cylinder bore was in outstanding shape and all I needed to do was a basic restoration to new condition.

A quick note here. 1979 Red Rockets were painted Tahitian Red, there was no powder coat match

for that color at the time. I had to find a part that was hidden from the sun and elements to use for

a color match. I found a powder coat company willing to produce a quantity of Tahitian Red powder

for me in gloss and satin. I also commisioned a company to color match the glyptal paint used to

coat the inside of the Magnesium castings.

A lot of the Magnesium parts were corroded and pitted which is quite common so I used a TIG

and some special sheilding gas and a Magnesium rod to fill weld the pitted surfaces. If this sounds

dangerous, it is, so don't try this at home.

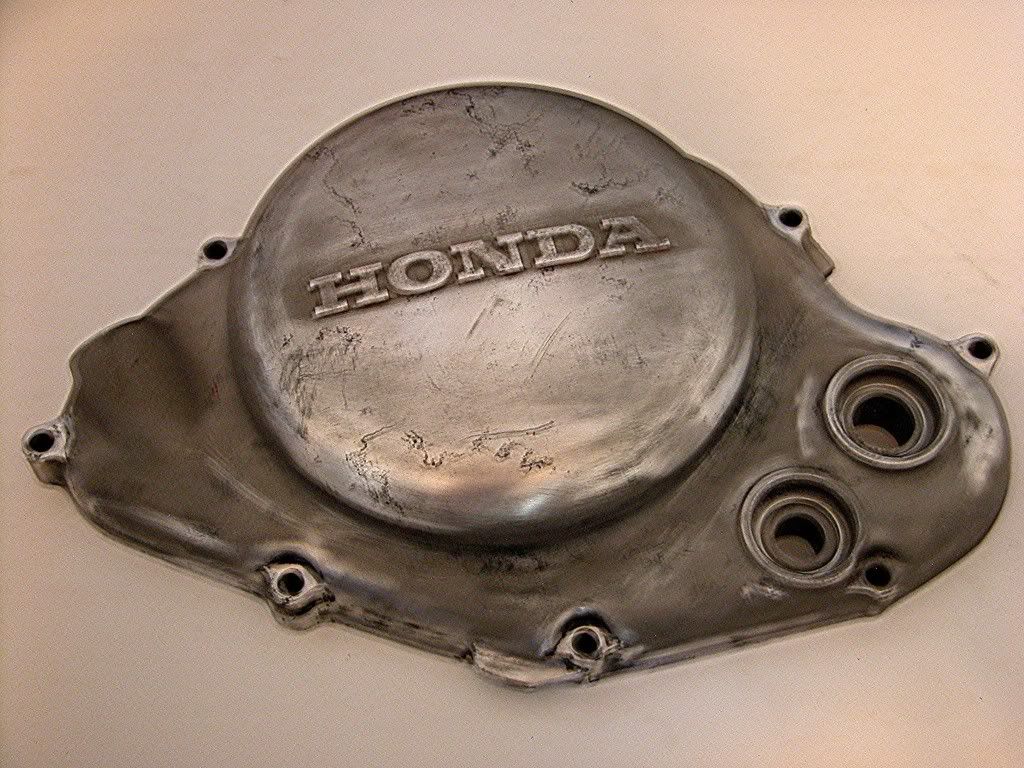

Right side case cover after media blasting and fill weld repairs

Finished Right side case cover.

Inside of Right side case cover with color matched Glyptal paint.

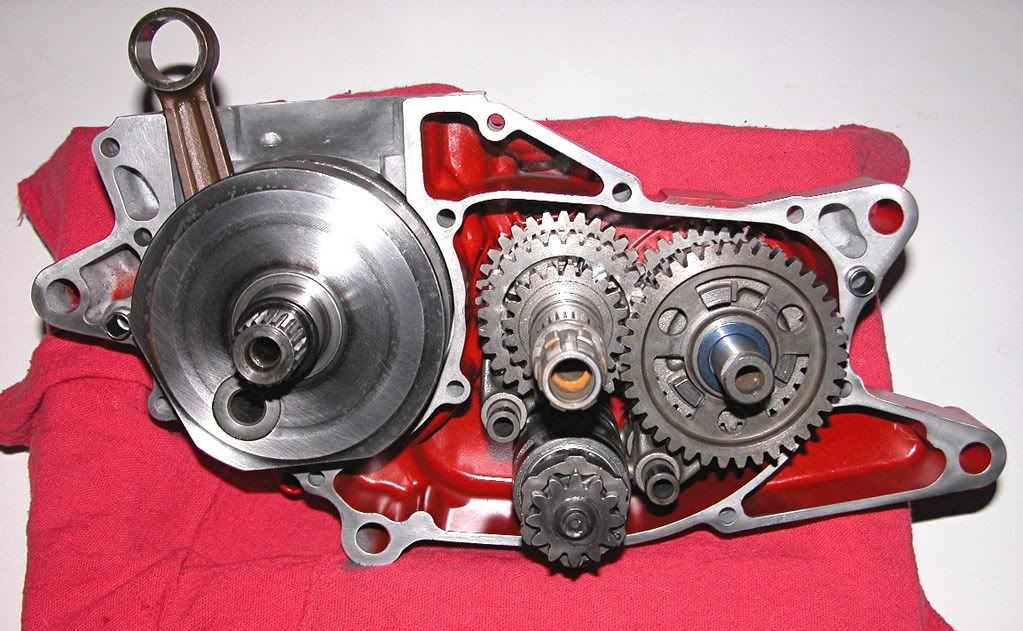

Finished Left side center case.

The transmission was treated to a NOS main and countershaft and all the gears were

NDIed and checked in tolerance. Any part that failed these tests were replaced. I also

replaced all of the thrust washers and circlips with new. I sent the crankshaft and a new

Honda rod and big end bearing to Racers Toy Store for a rebuild and balance. I also

replaced the shift forks, shafts and shift drum with NOS. The bottom end was now as

good as it was the day it rolled out of the factory.

Loaded right side case.

Next up was the ignition. Honda had several different ignitions lettered from "A" to "E".

The "E" ignition was supposed to be the best. This bike came with the "E" as seen

stamped on the tab at top Left.

Ignition cover with magnets removed (also not recomended) and media blasted

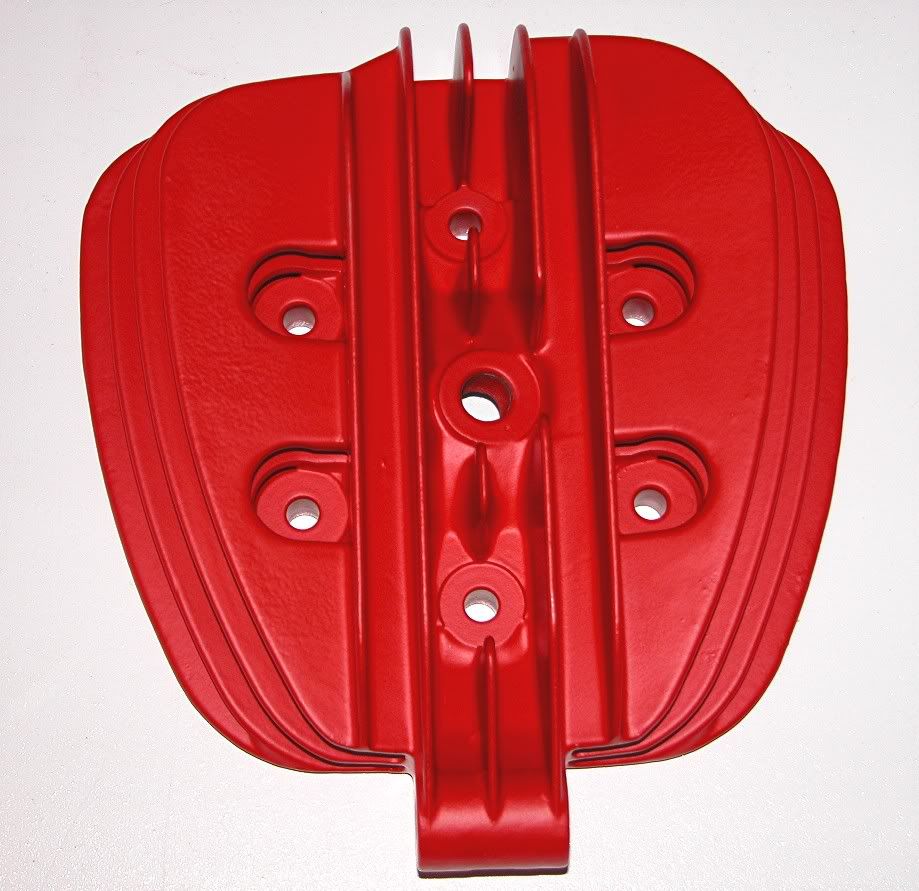

Ignition cover after powder coat.

Ignition cover with magnets installed and alligned.

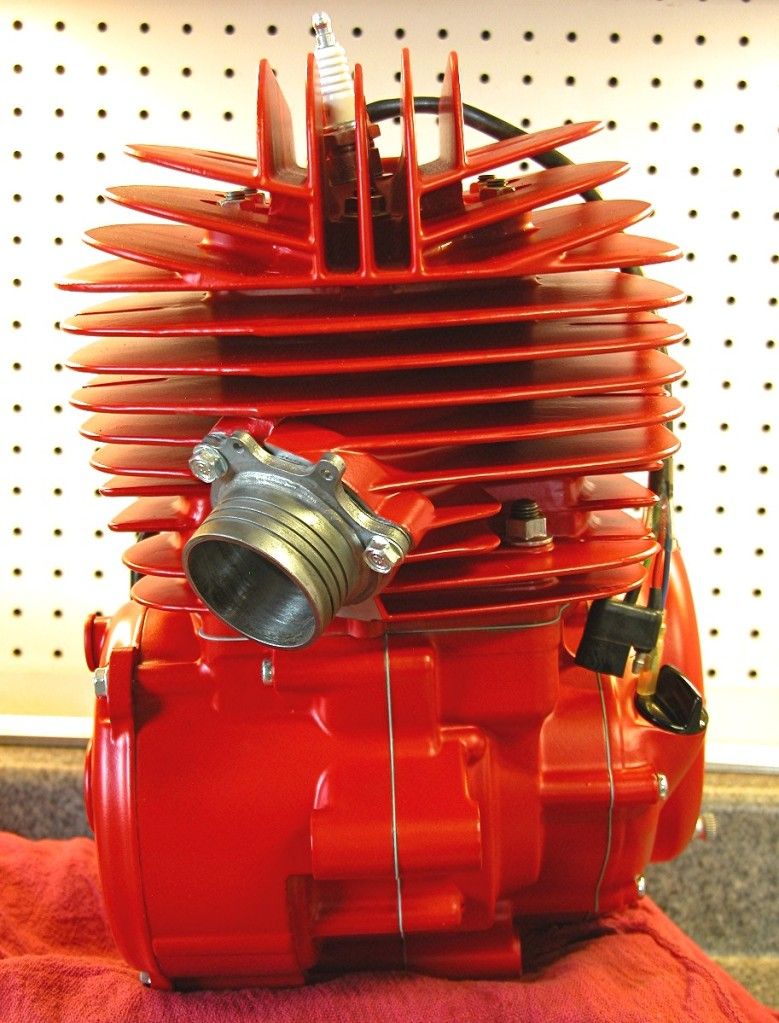

Restored and powder coated head.

Combustion chamber.

Cylinder after media blast, hot solvent tank, ultrasonic parts wash and powder coat.

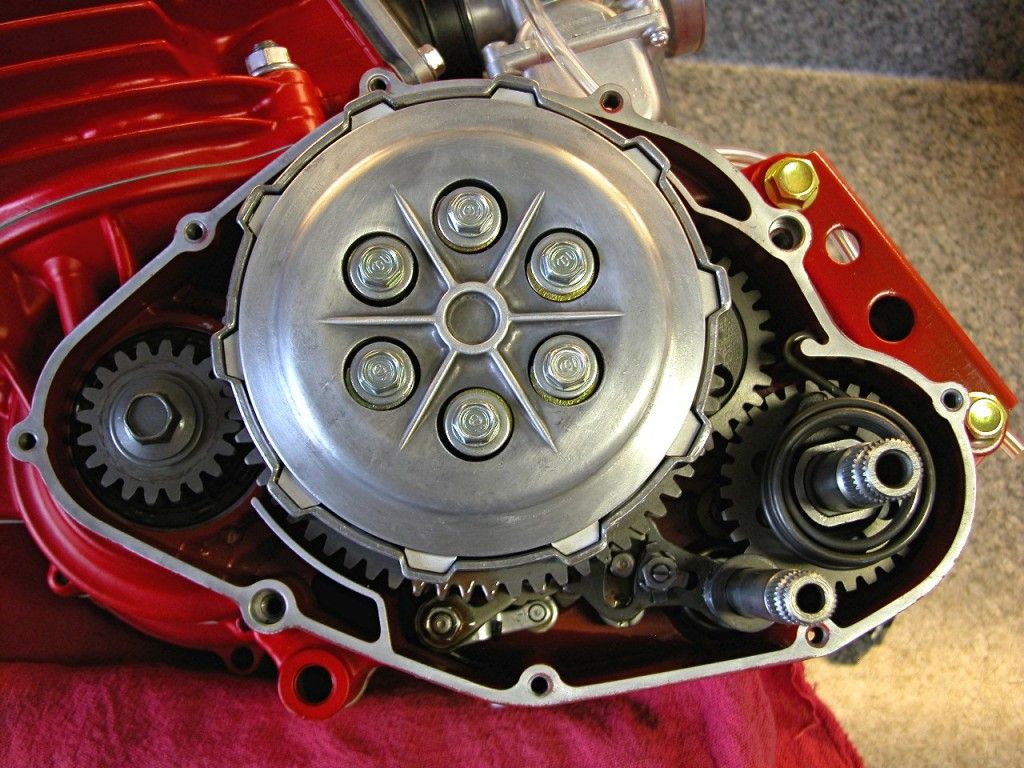

The Right side case was restored and all springs, pawls, plungers along with all of the

clutch components were replaced with NOS.

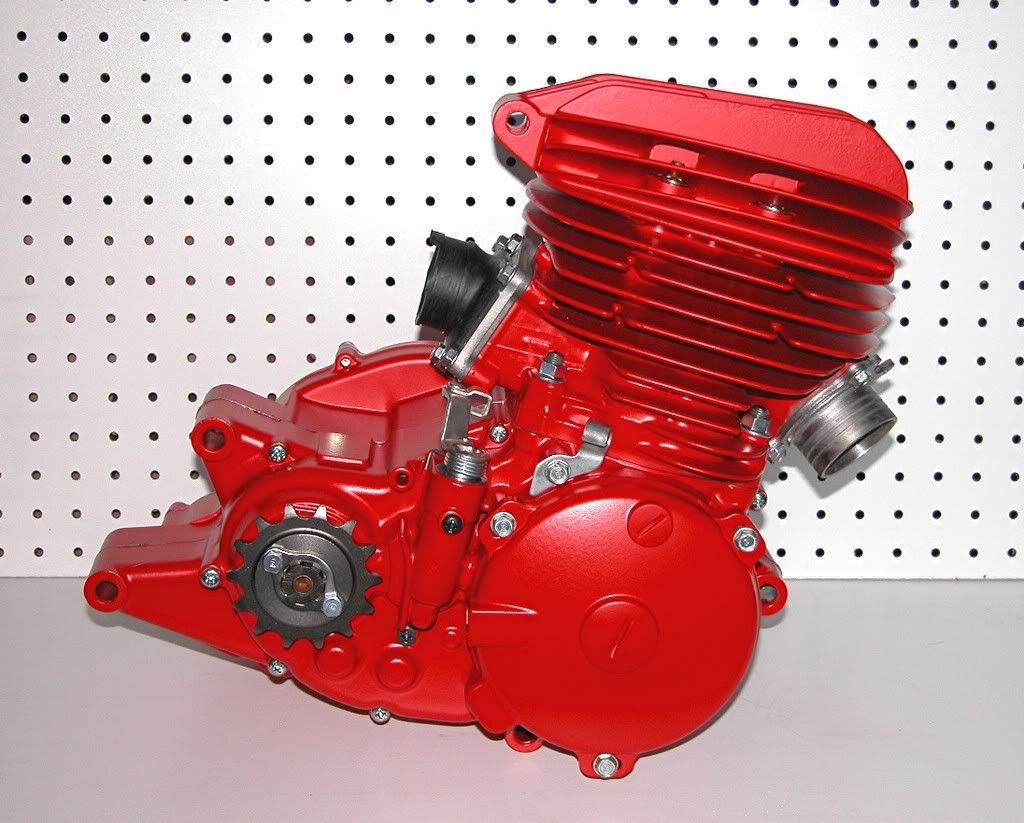

First test fit of the engine parts (no gaskets, no ignition)

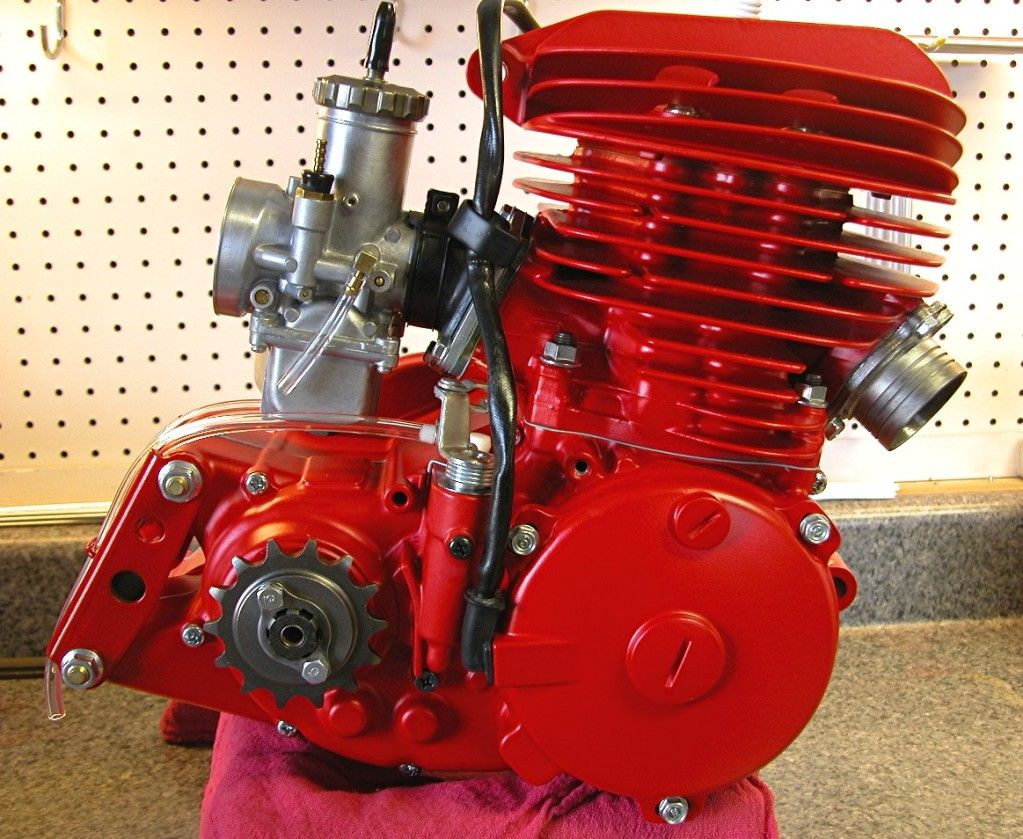

The carburetor got a trip through the hot solvent tank, then media blasted at low pressure

with crushed walnut shells. Then all the parts spent some time in the ultrasonic parts washer

followed by a complete rebuild replacing all the wear items and finished off with a NOS throttle

body top, NOS choke assemble and new hardware and vent hoses.

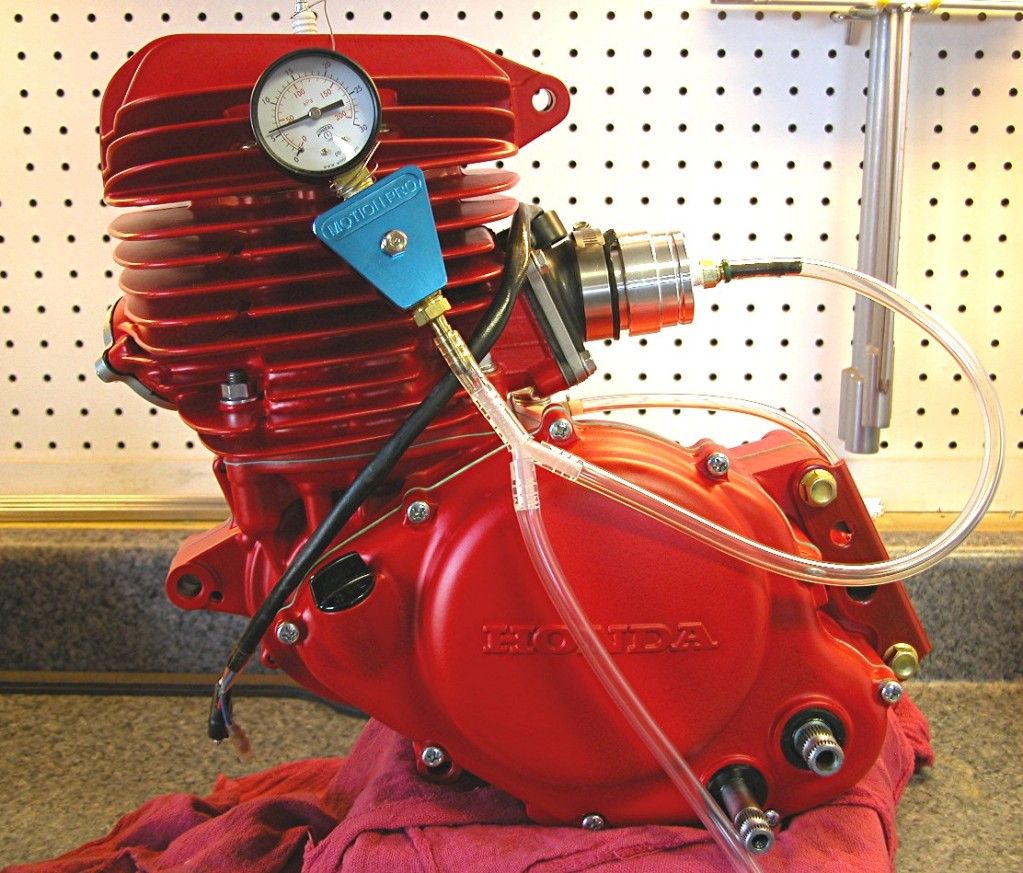

Finally, I re-assembled the engine with NOS Honda gaskets and performed a leak down test.

The engine maintained 6 psi for 7+ minutes, a nice tight engine.

Finished.

I'll post the frame resto process next.

dogger