The 500 conversion reached its decisive point today, as I cut the lower engine mounts and Y-piece out of the cradle. I used a Rigid Fuego Reciprocating Saw with a Bi-Metal blade, and will be going over the rough cuts with an aluminum sanding bit a la Dremel.

I am using the Conversion Parts 500 kit (available via eBay). There are several PDF instruction manuals published by this guy, and it has removed virtually all headaches and hassles normally involved with this sort of undertaking. Check them out here:

http://www.conversionparts500.comAs for welding, I am NOT the man for that task, so I have enlisted Brett Koufas of ICW Bikestands and Radiator Repairs/Mods to weld my fully jigged CR when the time comes (hopefully a couple weeks). ICW stands for "I Can Weld", so I think he'll do alright. He'll also be doing some big end tanks and new spigots on the already well-sized CRF radiators.

As the bike sat this morning:

First cut:

Both lower mounts off, I cut halfway in from both sides as it is on a slight bend in the cradle:

Now that the chunks are off, I'll go back through with a dremel and make them smooth. I took care to leave a large rectangular pad of material on the frame so there would be a little more meat to weld to than the very thin cradle tubing.

Next came extraction of the Y from the frame (only took one pic):

I'll be replacing the Y with this, a billet piece shot with walnuts to look cast:

In what I consider a backwards technique, I've started a project chassis first rather than engine first. It makes sense here, as while the engine is together I might as well mock up the frame. In order to line the sprocket up correctly, you need to use a set of swingarm collars from a 02-07 CR125. The shorter one is the left side, and the longer one is the right. This lined up the engine perfectly sprocket to sprocket.

The engine in frame, with swingarm pivot bolt through:

The collars:

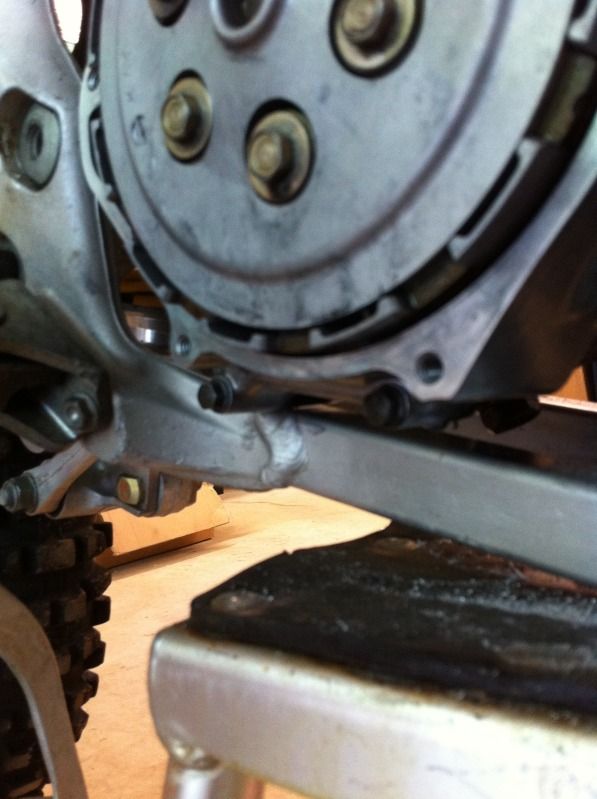

On the right side of the cradle, the inner clutch cover touches the frame, and needs about 2-3mm of clearance via an aluminum grinding bit on the dremel.

This will allow the engine to rotate into the supplied headstay:

The other bit of clearance-ing needed is almost 4mm off of the rear of the cases, much like how dogger315 has done, to clear the shock spring.

Here's the tool that did it, the old Y, the new Y, and my jig I bought from a vendor on

www.bannedcr500riders.com:

...and here's where I left off for the day.

So far I'd like to thank the exceptional dogger315 for providing careful advice on the CR250 clutch conversion via PM, as well as reputable shops and mods on part 1 of this build.

Once I get the mounts all fabbed up, the frame will come completely apart and will be blasted, and the only parts that will be polished are the upper extruded spars that run alongside the tank. The swingarm will be brushed. I will also start the engine tear-down as soon as the frame will permit, as I've been stocking up parts to do it.

Right now I'm using a 2000 CR250 complete ignition; research has proven it to work quite well. The digital ignition is a plus, but I'm not too sure if the light flywheel will be.

Stay tuned!