Looks like you have an amazing piece of work there. Thats gotta be pulling 55+ at the rear minimum

Thanks a bunch! Don't know what it's producing at the rear wheel, but it's enough to put a big

grin on your face.

I 'm thinking of possibly making a longer link, about 2mm, but then I need to mess with dropping the forks and or offset clamps.

Unfortunately, changing the length of the pull rods will not move the shock further from the case. Because the dogbone position is fixed, longer

pullrods will only rotate the dogbone counter clockwise. All this will get you is a change in the vertical axis for the shock (lower your seat height).

How much meat is in the case at that area where you coped it?

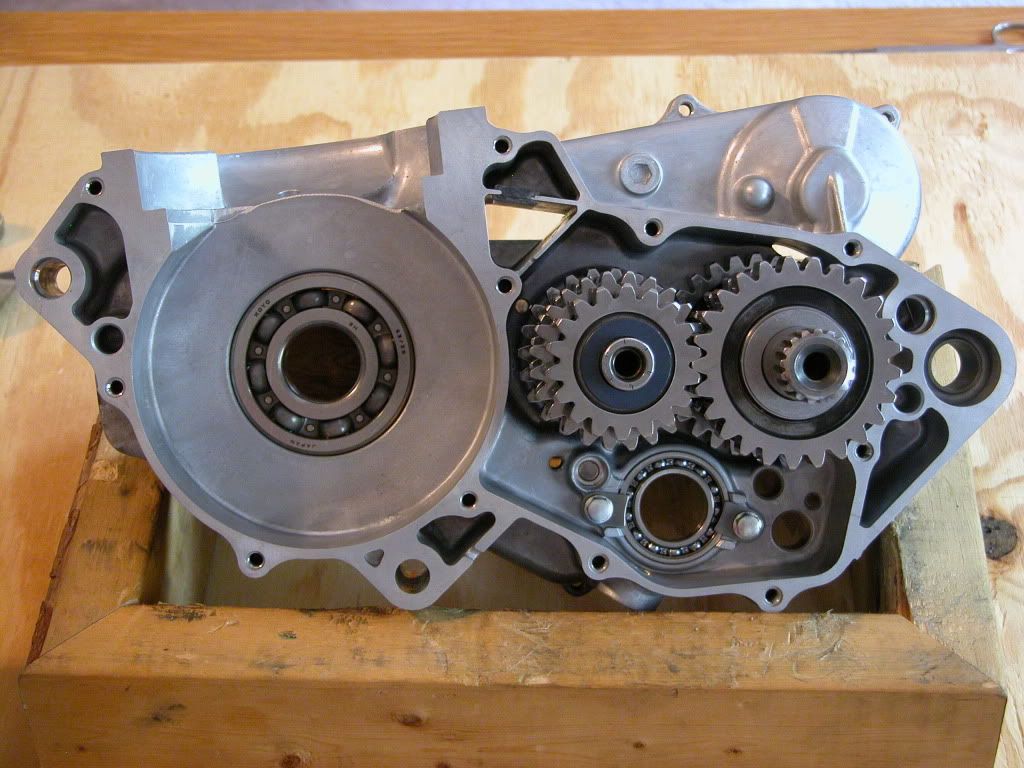

There is about 5mm. Here's a picture:

My Ti shock spring is rated at 5.3kg/m. It's the same diameter as a 5.8 kg/m steel spring.

Radiusing the case should work as well for your bike.

Is this the build that is posted on the cr500riders site?

if so are you still doing a CR250 conversion in the near future?

Yes, it's the same bike. I'm working on that CR250 project right now.

I am using a 2009 CRF 250R frame and adding a copy of a 2007 CR250 cradle.

I'm taking this conversion up a few notches. I used a handheld laser scanner

to scan the 07 and 09 frames and the 00 CR250 engine. The plan is to do all

the design work using CAD (SolidWorks), then produce the new cradle rails

and engine mounts with CAM. After a lot of digging, I finally sourced the radiused

corner square metric tubing that Honda uses for the cradle. The engine mounts

will be reproductions of the OE Honda mounts using 6061 Aluminum stock. I'm

using the hoop from an 07 CR250 donor frame, but the CRF hoop will work just

as good.

This conversion is proving to be much more difficult than the 500, partly because

of my insistence on no billet frame members, and partly because the CR250 engine

shape is more difficult to adapt.

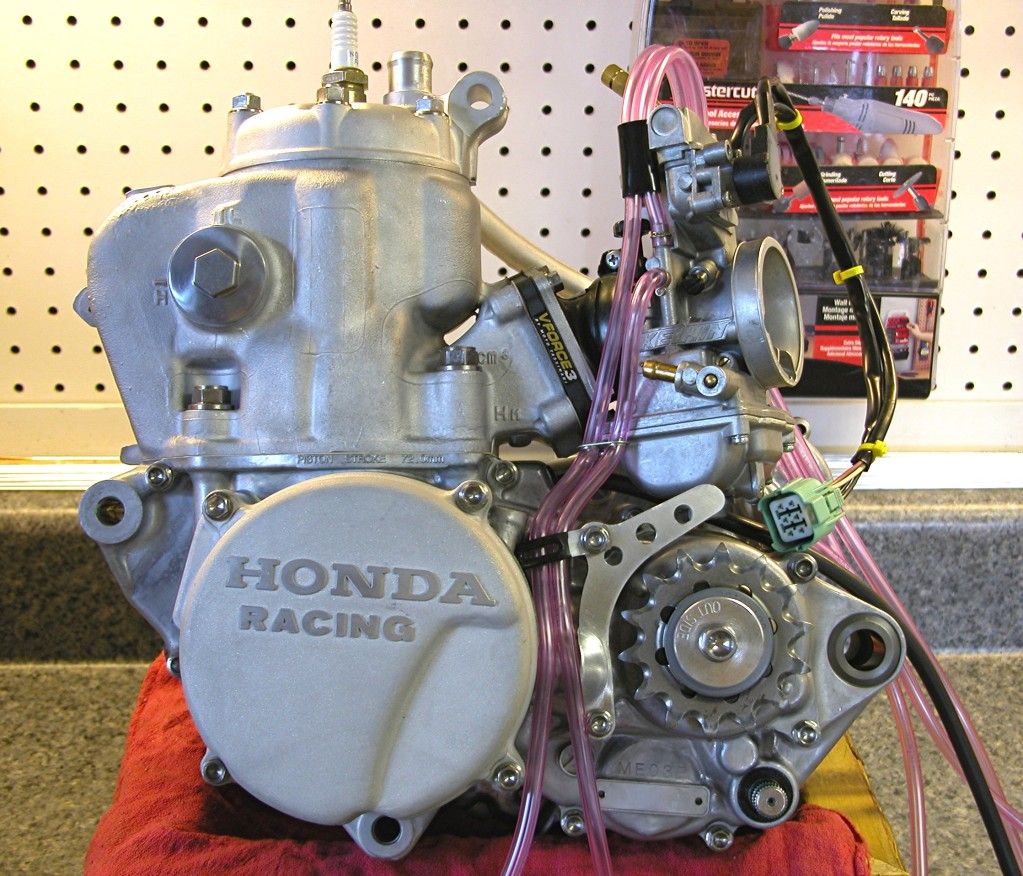

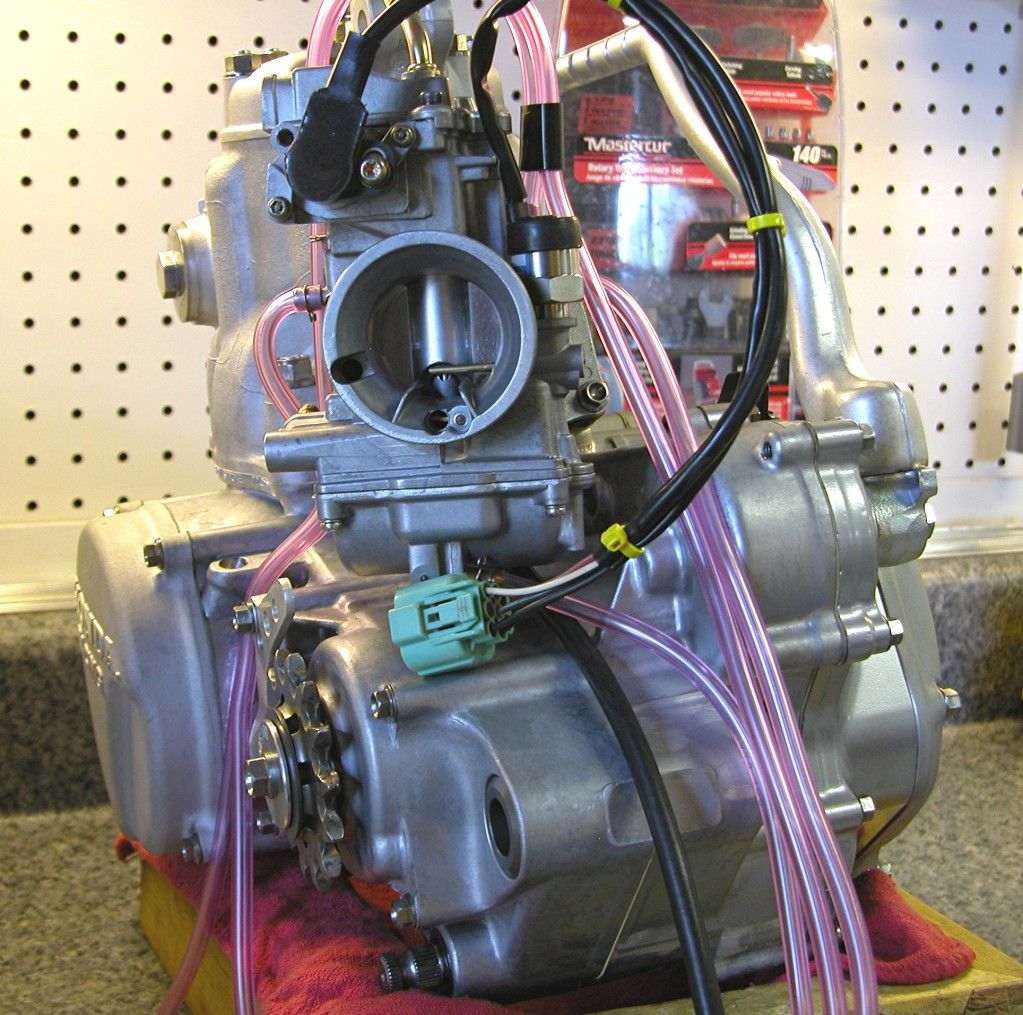

Here's a couple of pictures of the 00 CR250 engine I built for the bike:

If you have any questions, PM me. I'll be happy to fill you in.

dogger