Post by: Uniflow on September 24, 2012, 12:33:50 AM

Well certainly the first fuel injected Bighorn anyway.

Post by: TMKIWI on September 24, 2012, 03:19:07 AM

Post by: Uniflow on September 24, 2012, 03:45:15 AM

Post by: SachsGS on September 24, 2012, 03:03:49 PM

Post by: Uniflow on September 24, 2012, 08:45:06 PM

Post by: Uniflow on September 24, 2012, 09:09:28 PM

Post by: Uniflow on September 24, 2012, 09:16:08 PM

Post by: factoryX on September 24, 2012, 09:46:23 PM

Agreed.

Post by: 2T Institute on September 24, 2012, 11:16:05 PM

Post by: Uniflow on September 25, 2012, 07:22:29 AM

Post by: Coop on September 26, 2012, 01:15:40 PM

Post by: SachsGS on September 26, 2012, 03:43:01 PM

The Can Am's Rotax engine has an interesting history. Rotax began in Dresdan, Germany and was purchased by Fichtel and Sachs in 1932, whereupon production was transferred to Austria. In 1970 the company was sold to Bombardier of Canada and I've been told the rotary valved engines were already on the drawing board at this point.

Post by: citabjockey on September 26, 2012, 11:05:04 PM

Post by: Uniflow on September 27, 2012, 03:25:08 AM

These McCulloch engines use this system, crank cutaway running close to the crankcase. Exhausts are just for softies!

Post by: citabjockey on September 30, 2012, 06:18:03 PM

Put THIS flat four in your Vee Dub Bug!

LOL

Post by: 2T Institute on September 30, 2012, 11:13:40 PM

I wonder if anyone has ever considered using crank porkchops (i.e. not full round wheels) as a rotary valve mechanism instead of hanging that extra disk off one side of the crank?

Model car/boat/plane engines use that sort of a system. One system used on the Exactweld 250 was to use discs on both sides of the engine, with the timing staggered produced works type HP in the day. Disc is by far the best induction system, as it is not throttle dependent, reeds don't open unless the throttle is open.Kim Newcombe (RIP) went oh so close to winning the world 250cc road race title with a converted Koing boat engine. Moving the disc valve to the rear of the engine creates drive issues, which has traditionaly been a bevel drive or belt.

I've got a 1979 Gilera 125 MX with rotary valve induction in my collection, it looks like a Maico with a straight axle fork. If I'm not mistaken MZ pioneered disk intake valve technology in the 50's and when key people defected to the west this design made it's way to Japan (and your Bighorn - gotta love the name!).

The Can Am's Rotax engine has an interesting history. Rotax began in Dresdan, Germany and was purchased by Fichtel and Sachs in 1932, whereupon production was transferred to Austria. In 1970 the company was sold to Bombardier of Canada and I've been told the rotary valved engines were already on the drawing board at this point.

IIRC there is a 79 or 80 KTM 125 disc valve I was chasing a Gilera engine for road racing until the rules were changed to have a 82 cut off then got a hold of Rotax 124 engines, which are basicaly the Can Am 125 aircooled bottom end with an external water pump and a Rotax 256 cylinder. Easy 36-38HP

Any pics of the Gilera they are a nice bike

Any pics of the Gilera they are a nice bike

Post by: Uniflow on October 01, 2012, 12:13:45 AM

I have to agree with 2T, there is nothing like a rotary valve to offer unrestricted induction access to the crank case. Just needs a little control is all.

Post by: TMKIWI on October 01, 2012, 05:40:50 AM

Kim Newcombe (RIP) went oh so close to winning the world 250cc road race title with a converted Koing boat engine.

You mean the 500cc Champs.

Post by: 2T Institute on October 01, 2012, 12:28:35 PM

Post by: Uniflow on October 02, 2012, 08:06:56 PM

Post by: SachsGS on October 03, 2012, 04:01:39 PM

The Gilera is unusual in that it does not have primary kick.That long travel centre axle fork is different as well and produces some strange handling characteristics. The motor has zero bottom end and is very strong in the top end for it's era.

Post by: 2T Institute on October 04, 2012, 02:44:17 PM

Post by: Uniflow on October 05, 2012, 10:08:38 PM

Post by: Uniflow on October 05, 2012, 10:28:44 PM

Post by: 2T Institute on October 05, 2012, 11:02:20 PM

. I would be keen on some gears, I'll email you a exel file that takes the guess work out of it.Biggest benefit will be from a pipe as that pipe looks to short to me.

. I would be keen on some gears, I'll email you a exel file that takes the guess work out of it.Biggest benefit will be from a pipe as that pipe looks to short to me.

Post by: Uniflow on October 06, 2012, 01:24:52 AM

Post by: citabjockey on October 06, 2012, 04:28:28 AM

Sounds like you made some great progress on the maps!

First round of the VMX yesterday. The Bighorn foot peg broke off in the practice, lucky I found a farmer down the road with a welder. So a DNS for the first race. I've been having a lot of trouble with the off idle to approx 1/8 ish throttle. I made some last minute change's to the program the night before ( not tested ). What a difference! Easily the fastest in a straight line in pre 75, and pulls so much better than it ever has from the bottom of the rev's through to 8600. Still might need a little more advance down low or perhaps a little more compression or perhaps just some new rings. Gearbox is standard F9, so having a wide power spread is a good thing. F81M close ratio gearbox would be nice to have but they are almost unobtainium now. I will look at making some gears up, is anyone else interested in an F81M gearbox? If I find some pictures of the racing I'll post them.

Post by: Uniflow on October 06, 2012, 09:42:24 AM

No Maico's racing. The biggest problem with this bike is the lump on it. I need to be way fitter, I can hardly hang on to it after only a few laps, not the bikes fault.

Post by: 2T Institute on October 06, 2012, 10:20:27 AM

Post by: SachsGS on October 06, 2012, 04:53:01 PM

Post by: Jeram on October 07, 2012, 01:30:45 PM

Just found another problem. When the voltage goes below six or seven volts ( old battery ), the Ignitec has been defaulting to some fourstroke program! Keeps looking for a cam sensor, no spark. I've changed the default to the program I use now. There is a charging system so when the engine is running, no problem it's just if the voltage drops when starting. This system should now be able to run with just a capacitor.

Perhaps thats why my CRM supermoto doesnt like kick starts???

can you PM me with how exactly you fixed this?

my current fix is Iv installed a total loss 200gram UPS 12v battery behind the number plate. I hit a button on my throttle which connects it and turns on the ignition with a pure 12V for a few seconds till its idling nicely then I disconnect it. being a UPS battery it should last 2-3 years without being charged.

Post by: Uniflow on October 27, 2012, 10:24:58 AM

Bighorn in the Acerbis four hour this weekend.

Post by: Uniflow on October 27, 2012, 10:26:38 AM

Post by: Uniflow on October 27, 2012, 10:31:48 AM

Post by: TMKIWI on October 28, 2012, 05:40:14 AM

How did you go.

Post by: Uniflow on October 28, 2012, 09:33:25 AM

Post by: Uniflow on October 28, 2012, 09:40:51 AM

Post by: TMKIWI on October 28, 2012, 10:14:52 AM

Post by: Uniflow on December 09, 2012, 07:28:57 PM

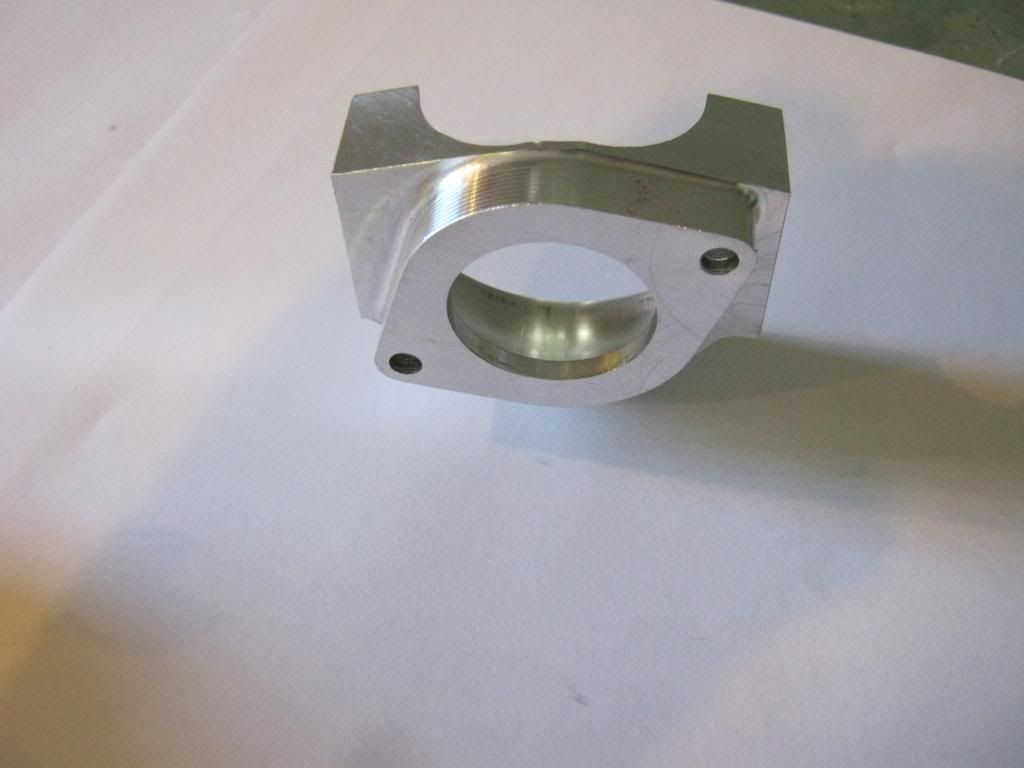

The new throttle body for the bighorn. The "in cable" TPS I'm using is not accurate enough.

This unit will have the TPS on the end of one of these shafts. Hole is 36mm, shafts are 8mm

This is a ball valve type throttle body to replace the slide type I'm using now. Air is drawn from the cavity on the side of the engine so no air cleaner is needed to bolt straight to the throttle body like a normal twostroke ( modern reed type ).

Post by: Jeram on December 10, 2012, 01:25:10 AM

did you try the RGV style TPS's where you run a cable spliter to a frame mounted TPS

Post by: Uniflow on December 10, 2012, 01:51:35 AM

The ball valve should make a good throttle valve,when the ball valve is open there is no restriction to airflow, no gaps, no needles, no butterfly, nothing but a nice big bell mouth straight in. Plus it shortens the intake path a little more too.

Jeram, what happened too this Bighorn road racer guy that was going to get back to us? On NATF

Post by: Uniflow on December 11, 2012, 12:07:37 AM

Post by: Uniflow on December 11, 2012, 12:11:41 AM

These are the cylinders I was telling you about.

These are some port molds, one casting resin and the other transfered to Alloy ( for shell sand, 200 degrees C )

Post by: factoryX on December 11, 2012, 06:45:10 AM

Post by: 2T Institute on December 11, 2012, 07:46:59 AM

Post by: Uniflow on December 12, 2012, 01:05:21 AM

Here are some cores for a uniflow twostroke engine cast here. First core is CO2 hardening sand, exhaust cylinder,second core is shell hot set sand ( yellow ), transfer port.

Post by: SachsGS on December 12, 2012, 02:59:11 AM

Post by: Uniflow on December 12, 2012, 05:30:07 AM

Post by: Uniflow on December 12, 2012, 08:19:41 AM

Then these need to be copied back into a core box, so you can make more of them ( in casting resin for the cylinder pattern itself ) and ultimately these boxes will make the hard sand cores you cast with. Basically you manufacture the cores first ( in casting resin ) stick them all together, then add thickness on top of that.

This is the pattern being made up of the resin core prints. What is solid here will be holes in the casting ( when done in sand ).

This is the main cylinder and exhaust port as one core, here is the box it's made in.

Here is the pattern made with all the smaller cores glued inside. You can see the core prints ( tapered bits on the ends) sticking out. This gets invested into sand then removed. While the sand mold is apart, hard sand cores are fitted ( transfers / water gallery etc ) They will fit neatly into the core prints provided by the mold as it was invested. With the mold back together and cores in place, metal is poured in. Where there is sand ( as in a core ) there will be a hole ( port ).

Thought I had some pictures of the sand mold set up and pouring, but must have deleted them?

I have others but not of twostroke parts.

Post by: Uniflow on December 12, 2012, 08:28:07 AM

Post by: Uniflow on December 12, 2012, 08:34:00 AM

Post by: Uniflow on December 12, 2012, 08:36:07 AM

Post by: 2T Institute on December 12, 2012, 01:47:02 PM

Post by: SachsGS on December 12, 2012, 03:10:33 PM

Post by: Uniflow on December 12, 2012, 07:32:15 PM

Fuel pump is by gravity and it's running on ethanol ( with a little castor ).

Post by: Uniflow on December 12, 2012, 07:33:31 PM

Post by: Uniflow on December 12, 2012, 07:36:58 PM

Post by: 2T Institute on December 12, 2012, 08:39:35 PM

Post by: _X_ on December 12, 2012, 10:13:21 PM

Post by: Jeram on December 12, 2012, 10:34:04 PM

Post by: Uniflow on December 12, 2012, 10:42:42 PM

Post by: _X_ on December 12, 2012, 11:03:08 PM

Post by: Jeram on December 13, 2012, 02:31:06 AM

Post by: factoryX on December 13, 2012, 04:35:59 AM

Casting, pattern making and machining are my hobby and job. So if I get a little carried away just say so. To cast a twostroke cylinder first you need cores then a pattern. I make my cores often with a rubber mold of a cylinder I like the port shape of, then copy into a two pot casting resin. So you end up with ( male ) transfer port shapes like this.

Then these need to be copied back into a core box, so you can make more of them ( in casting resin for the cylinder pattern itself ) and ultimately these boxes will make the hard sand cores you cast with. Basically you manufacture the cores first ( in casting resin ) stick them all together, then add thickness on top of that.

This is the pattern being made up of the resin core prints. What is solid here will be holes in the casting ( when done in sand ).

This is the main cylinder and exhaust port as one core, here is the box it's made in.

Here is the pattern made with all the smaller cores glued inside. You can see the core prints ( tapered bits on the ends) sticking out. This gets invested into sand then removed. While the sand mold is apart, hard sand cores are fitted ( transfers / water gallery etc ) They will fit neatly into the core prints provided by the mold as it was invested. With the mold back together and cores in place, metal is poured in. Where there is sand ( as in a core ) there will be a hole ( port ).

Thought I had some pictures of the sand mold set up and pouring, but must have deleted them?

I have others but not of twostroke parts.

So badass I nearly fell out of my chair haha

Post by: Uniflow on December 13, 2012, 04:41:04 AM

Post by: Jeram on December 13, 2012, 05:34:30 AM

(the answer is yes)

Id love to be able to take a few days of work some time to fly over to you and see you do this whole process from start to finish. it seems like a VERY handy skill set to have!

Post by: TMKIWI on December 13, 2012, 06:42:12 AM

were you hoping we could call him Aluminium-Member? LOL

He does look a little like the man in question. Only taller.

Post by: Uniflow on December 13, 2012, 07:21:45 AM

Post by: SachsGS on December 13, 2012, 03:30:08 PM

www.retrotrials.com/mecatecno.html

Post by: Uniflow on December 13, 2012, 09:18:33 PM

Post by: bearorso on December 14, 2012, 05:08:21 PM

Well, second part to the " don't use that bloody furnace again " was we had an explosion while tipping excess alloy into a pot on the ground. There was a little dampness in the pot. NEVER tip molten alloy into a wet pot!!! The alloy went straight up into the air, must have gone quite high as it took a while to rain down again. My mate ran into the shed while I ran out into the paddock ( being NZ it was with the sheep ) > The alloy was still quite hot and I got burnt in the hair and down one boot. Unfortunately the wife saw it all and along with the crack in the crucible that was the end of that!! No sheep caught fire.

This what happens when you mix business with pleasure, Uniflow!

When Will You Kiwis Ever Learn?

Keep your concubines away from you when you are working - too much of a distraction.

Their a Weird Mob in Un Zud, they have far to close a relationship with their Jumbucks!

Sick Puppies, the lot of them.

Post by: SachsGS on December 15, 2012, 12:26:39 AM

Post by: Uniflow on December 15, 2012, 04:16:12 AM

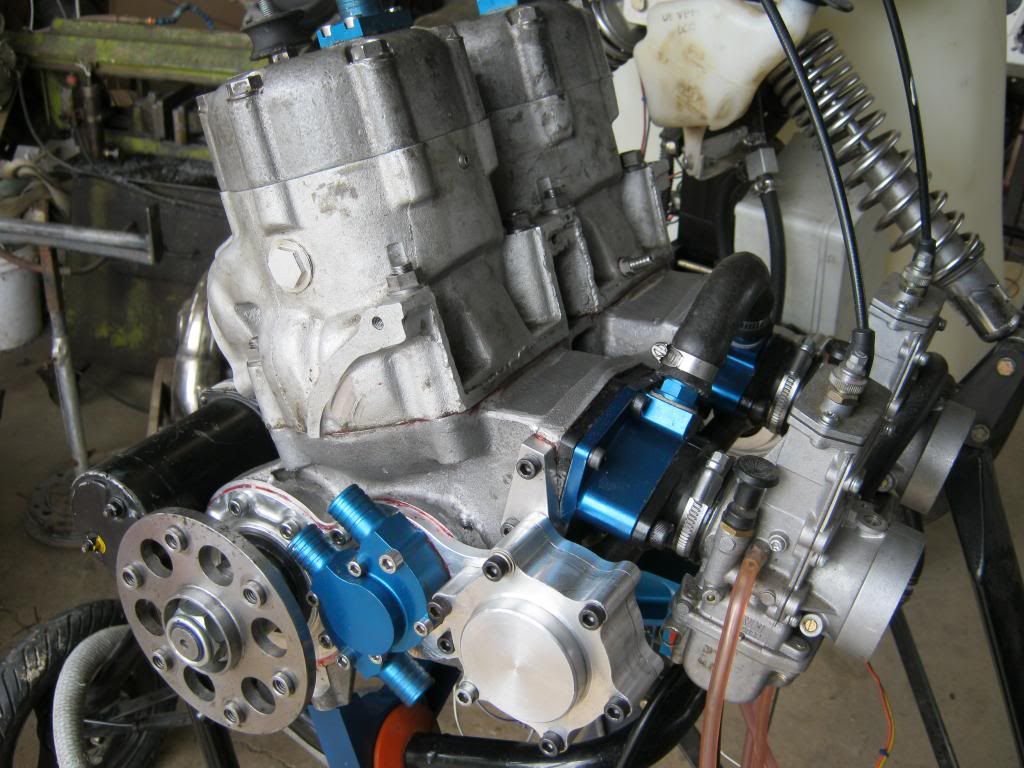

The ball throttle in place with TPS on the end. Nice big ( well 36mm anyway ) hole straight in. This is with the variable valve open. Try viewing your crank on a reed engine like this! This has got to work better than a slide? Nothing touches, ball valve runs on bearings. Next, see how it runs.

The map will have to be changed now, different airflow verses TPS positions.

Post by: Jeram on December 15, 2012, 04:28:01 AM

there are some SAE papers which suggest that with some slight adjustments to the shape of your valve that you could gain some decent CFM improvements.

Mainly they just found the optimum radius compound curves and lengths for making HP. Its based on the bell mouth of a carb/throttle body but should be perfectly applicable to your application!

what you've got looks pretty darn close though, but it'd be interesting to measure how close it is to 'perfect'.

Post by: Uniflow on December 15, 2012, 05:07:55 AM

The bighorn doesn't need more power, I just need to ride better but if more power is available, I'll take it!

You know, it's a trail bike, steel wheels, steel tank, steel guards and I'm not little. So if I've got a power advantage, good on me.

Sounds like I'm making excuses, I am.

Post by: Uniflow on December 15, 2012, 05:15:34 AM

Post by: Jeram on December 15, 2012, 07:02:53 AM

Perfect, measure, what are these words??? Unfortunately I'm a bit " that looks about right " sometimes. It's a matter of what would fit / look right / what I know about 3D on the CNC ( not always enough ) and time. Hey it's a first up, lets see what happens?

The bighorn doesn't need more power, I just need to ride better but if more power is available, I'll take it!

You know, it's a trail bike, steel wheels, steel tank, steel guards and I'm not little. So if I've got a power advantage, good on me.

Sounds like I'm making excuses, I am.

whack her on the dyno and be sure to video it

Post by: _X_ on December 15, 2012, 03:23:15 PM

Post by: Uniflow on December 15, 2012, 08:55:01 PM

I must be getting old, this would be the first time I've done this, left a rag in the exhaust port.

It would only fire a few times than stop??? A few minutes and the penny dropped.

Post by: _X_ on December 15, 2012, 08:59:09 PM

Post by: Jeram on December 15, 2012, 11:26:26 PM

Post by: Uniflow on December 30, 2012, 07:14:27 AM

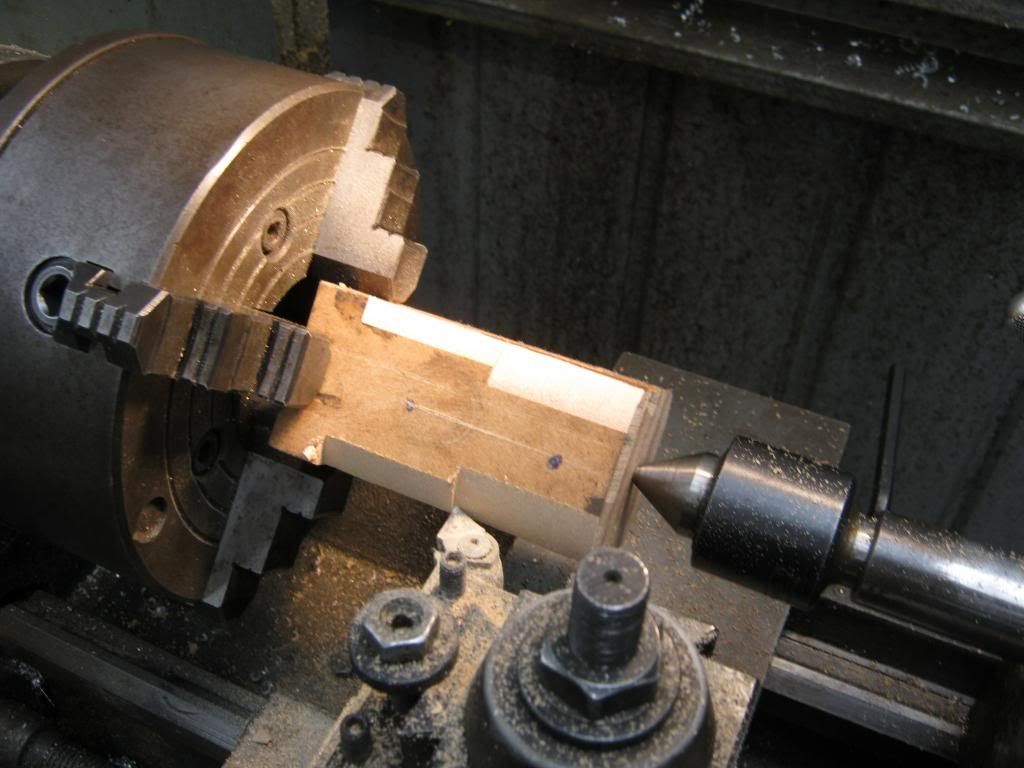

This is the beginning of a rotary drum throttle body ( for EFI ) on a YZ 250.

This is the core and core box manufacture. Rather than explain I'll mostly just show pictures.

Post by: Uniflow on December 30, 2012, 07:20:43 AM

This is the core box finished, a real pattern maker would paint it, I cant be bothered.

The core box will be used to make hard sand core prints ( CO2 setting sand, cold process ).

The original core will now be used to build up the actual pattern on to.

Post by: 2T Institute on December 30, 2012, 07:39:50 AM

Post by: Uniflow on December 30, 2012, 09:18:24 AM

The gue? is that two pot casting resin I showed earlier. Core has a waxing agent painted on. Use kiln dried pine, best for gluing or I use Armorboard, it's sort of like custom wood only much more glue used to make it. It's heavy and machines like alloy, leaves a nice smooth finish. Glues good too also very stable but don't leave it on your machines as it's abrasive.

If I do some more tomorrow I'll post pictures also.

2T, that ball valve throttle on the Bighorn works a treat!! I've been riding round the back yard with the laptop zippy tied to the tank tuning it, up to approx third throttle. I don't think the laptop likes it too much.

Post by: Uniflow on December 31, 2012, 04:32:41 AM

These pictures show building up " thickness " to the original core. You can see the ends of the core sticking out of the pattern. The core will be made of sand so the molten alloy will run between the inner sand core and the outside of the mold shape that has been left behind in the mold box. This will leave us a cast hollow item. When the foundry opens again I'll get pictures of setting the mold and pouring alloy.

Post by: 2T Institute on December 31, 2012, 08:02:25 AM

Lucky the pictures are in English

Post by: SachsGS on December 31, 2012, 04:27:47 PM

Post by: Uniflow on January 01, 2013, 12:07:38 AM

Post by: 2T Institute on January 01, 2013, 12:42:18 AM

Fascinating, is Augusto Morini of Moto Morini fame? How much of the sand remains behind in the casting and how does this affect the followup machining?

No it's Gabriel Gnani he is apparently a VERY wealthy man, he does all that in a very well equipped workshop with a few retired Italian artisans, just for the love of it. His 125 went very well with a top line young rider on it and only slightly slower with Gabriel on it. He is a legend in Italian bike racing and helped get the ICCGP concept off the ground.

Post by: bearorso on January 01, 2013, 07:28:08 AM

I don't think the laptop likes it too much.

I'd say so - visions of that set up have me (respectfully) chuckling away.

Brilliant stuff , Uniflow.

I've Never had anything to do with castings - I'm enjoying seeing / reading your progress. A new YZ top end, with the ability to go bigger in bore size, with your EFI, could certainly find a market. I went into that 'Micro' Dirt Track car / karts world, via the Internet, and it seems like a big market. Though, there may be restrictions on induction methods?

?? Karting seems to restrict induction systems, to keep costs in check.

?? Karting seems to restrict induction systems, to keep costs in check.Your a clever Kiwi - geeze I Hate praising Un Zudders!. They are 'orrible

Post by: Uniflow on January 11, 2013, 02:25:21 AM

Here is a little of the development of the Bighorn. Video is mostly by "accident" ( someone happened to have a camera around at the time) so it's just a lot of jumbled bit's of video from a friend of mine. Most was with the Lake Injector ( copy ) and some with the early days of EFI, still had a lot of tuning to do. Actually still finding bits in the computer I didn't even know was in there. I'm sorry the pictures are not so good but at least you can see it runs.

Post by: _X_ on January 11, 2013, 02:46:31 AM

Post by: Jeram on January 11, 2013, 07:02:38 AM

Post by: SachsGS on January 11, 2013, 04:36:53 PM

Post by: Uniflow on January 16, 2013, 09:32:16 AM

No, if ever I see you, the pints are on me!! That Lake injector was a @#$%^ to tune I'm glad it's gone.

Post by: 2T Institute on January 16, 2013, 11:01:22 AM

Post by: _X_ on January 16, 2013, 10:35:09 PM

Post by: Uniflow on January 17, 2013, 12:11:41 AM

Post by: 2T Institute on January 17, 2013, 12:36:52 AM

Post by: SachsGS on January 17, 2013, 03:06:18 PM

Post by: Uniflow on January 18, 2013, 02:24:03 AM

Post by: _X_ on January 18, 2013, 02:28:53 AM

Post by: Uniflow on April 23, 2013, 12:04:48 AM

YZ 250 is running, problems with the injectors being too big so we are waiting for some smaller units.

Injector on times are too small to get the mixture right. Do you know the biggest problem we have here in NZ is getting stuff, no one stocks anything and to order out of the US you have to be sure it's what you want before they send it and trying to ask technical questions over the phone to some parts packer is impossible. Half of them can't even read a ruler, keep telling me sizes in something called " inches " ?

Post by: citabjockey on April 23, 2013, 12:09:19 AM

Now its time to really make that bike fly. Find a roached 250F and put that way cool aire cooled 2T EFI motor in there!

Well we did it, The Bighorn, second in the VMX series. Certainly the bike is good enough for first just not the rider. EFI performed flawlessly all season only problems was a foot peg falling off ( this was the only DNF ), gearbox bearing failure ( at a trail ride but still finished the ride ) and a regulator issue that was found half way through the season but this didn't affect five lap races. I'm not sure if an EFI twostroke has finished with a place in a national MX series before? I would imagine it would be the first EFI Bighorn Kawasaki to do this anyway! I'm just saying EFI does work.

YZ 250 is running, problems with the injectors being too big so we are waiting for some smaller units.

Injector on times are too small to get the mixture right. Do you know the biggest problem we have here in NZ is getting stuff, no one stocks anything and to order out of the US you have to be sure it's what you want before they send it and trying to ask technical questions over the phone to some parts packer is impossible.

Post by: Uniflow on April 23, 2013, 12:21:24 AM

Post by: citabjockey on April 23, 2013, 12:39:54 AM

I need to just lock the door to the workshop and tell every else to bugger off.

Post by: Jeram on April 23, 2013, 03:16:08 AM

Post by: Uniflow on April 28, 2013, 07:42:51 AM

There you go Racer X , I do get off the seat sometimes.

Click on the picture and it will take you to lot's of photos from the final VMX round in NZ.

Meagan is there riding the 175IT and the TT500.

Post by: citabjockey on April 28, 2013, 05:57:46 PM

Post by: Uniflow on April 28, 2013, 08:46:57 PM

Post by: Turquine on April 28, 2013, 09:25:38 PM

Post by: Uniflow on April 29, 2013, 01:47:27 AM

You still don't have that F81M do you?

Post by: Turquine on April 29, 2013, 10:42:15 PM

Post by: Uniflow on April 29, 2013, 11:54:53 PM

At 7000 it had about 15HP, at 7500 probably did about 30HP! Would go through to 9000. NOT a good trail bike. Either monstrously out of control or bogging.

Post by: _X_ on April 30, 2013, 11:46:59 PM

HA! good show uni!

There you go Racer X , I do get off the seat sometimes.

Click on the picture and it will take you to lot's of photos from the final VMX round in NZ.

Meagan is there riding the 175IT and the TT500.

Post by: Uniflow on June 24, 2013, 08:16:28 AM

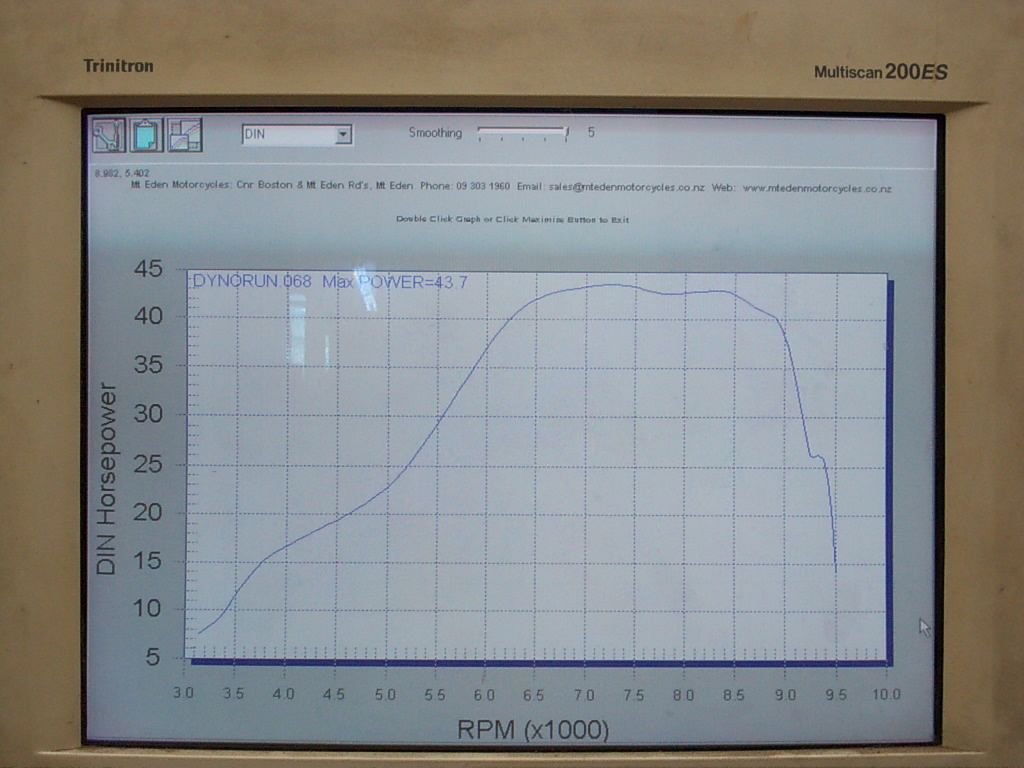

Ran the old girl on a dynajet dyno Sunday, not too bad, exhaust is only 186 degrees open time. Cut off is rev limiter cutting in, fueling is not too far off. This is rear wheel HP.

Did a run with the YZ 250 EFI as well.

Post by: TMKIWI on June 24, 2013, 09:28:10 AM

Post by: Uniflow on June 24, 2013, 09:39:11 AM

Post by: TMKIWI on June 24, 2013, 09:45:33 AM

Plus another 10hp on top.

Post by: Uniflow on June 24, 2013, 09:54:27 AM

The new engine is going to have to put out 65 or more (Crank HP), I want more than any 450F can muster!

This Bighorn has very old cylinder Tec on it I haven't done anything to the ports apart from cleaning the burs around the transfers and raising the barrel a bit. And widening the exhaust a bit.

Post by: citabjockey on June 24, 2013, 03:18:49 PM

These injector projects of yours are just so impressive, Thanks for doing this and posting your work and results!

There is a video of the Bighorn on the dyno coming up soon, it's somewhat more " uncivilized "

The new engine is going to have to put out 65 or more (Crank HP), I want more than any 450F can muster!

This Bighorn has very old cylinder Tec on it I haven't done anything to the ports apart from cleaning the burs around the transfers and raising the barrel a bit. And widening the exhaust a bit.

Post by: Uniflow on June 29, 2013, 04:19:11 AM

Post by: Flettner on November 14, 2016, 02:41:21 PM

https://youtu.be/CnIemdISKrM