Post by: TCI Performance on October 07, 2012, 02:17:52 AM

I am currently past the half way point and in the middle of manufacturing custom parts at this point. The initial engineering, FEA and function checks have been completed and moving forward in putting all the pieces together.

I will be posting some pictures of different stages as I am moving towards the completion of the first build.

I hope you will all enjoy it.

The Victim

2006 YZ250 2-Stroke

The Objective

To update and make something that's good even better.

Updates will include the following:

* All new Aesthetics

* Engine Relocation

* Both Front and Rear Suspension Mods

* Chassis/Frame Modifications

* Upgraded Plastics

* New Graphics

* Loose 5-7lbs of original weight

* Engine Mods

* Newly designed sub frame

* Custom Exhaust System

* And more........to keep it interesting.

I will update with pictures and write up's as mentioned but It won't be on a daily basis rather a weekly kind of thing so please have patience as I don't work on it all day every day.

I know this is not too exciting yet but they all start off looking like this.

One thing I can promise is that when I'm done with her she will be one of a kind.

Post by: Charles Owens on October 07, 2012, 04:27:43 AM

Post by: citabjockey on October 07, 2012, 04:42:06 AM

Going to be watching this thread.

Post by: TMKIWI on October 07, 2012, 05:57:08 AM

" engine relocation" ? like to see how and why.

Will watch with interest.

Post by: scotty dog on October 07, 2012, 12:16:04 PM

Post by: Jeram on October 07, 2012, 01:24:18 PM

question: if the engine relocation has to do with the counter shaft postion wouldnt it be simpler to modify the frame to accept an adjustable swing arm pivot height system that allows changes by swaping inserts, or an eccentric rotating system?

That way you dont have to guess where it needs to be for all scenarios, you can tune it to find the optimum position for each track

Post by: cnrcpla on October 07, 2012, 05:12:32 PM

I can't wait to see the progress

I can't wait to see the progress  If your moving the engine I think fuel injection would be a good option because it might fit better (depending on where the engine is going

If your moving the engine I think fuel injection would be a good option because it might fit better (depending on where the engine is going  )

)

Post by: Logan Dewey on October 07, 2012, 05:50:39 PM

Post by: factoryX on October 07, 2012, 07:37:27 PM

Post by: Uniflow on October 07, 2012, 08:29:42 PM

Post by: _X_ on October 07, 2012, 10:05:56 PM

Post by: citabjockey on October 08, 2012, 02:44:54 AM

Lower the engine and gas tank down to lower the center of gravity would by far be the most beneficial by making the bike feel even lighter. Lets take a step back in time and look at honda:

Post by: factoryX on October 08, 2012, 03:09:55 AM

Post by: TCI Performance on October 08, 2012, 04:28:18 AM

* Fuel injection is on the list but most likely will not be released into the first build as I want to test the carburetor version first.

* The main and sub frame will and have been cut and modified to accept numerous changes for the pipe, engine, radiators and air box.

* Lower CG will be achieved with the changes mentioned above.

The bike has already been built back up with the mock up modifications in order to assure proper fit, form and function and I am now in process of manufacturing the actual pieces and other required parts in order to weld up the main and sub frame. After that has been done the frame will be properly processed and once I get the frame back it will go pretty quick to build it up as everything should just bolt on. Assuming everything goes by plan I should be able to release the first finished pictures by this month end with test rides and write up's to follow.

Can't wait for it to be done and share it with everyone.

Post by: TMKIWI on October 08, 2012, 06:13:39 AM

* The main and sub frame will and have been cut and modified to accept numerous changes for the pipe, engine, radiators and air box.

You turning the cylinder around , aren't you.

Post by: 2T Institute on October 08, 2012, 11:59:56 AM

Post by: factoryX on October 08, 2012, 11:57:58 PM

Post by: Coop on October 09, 2012, 12:08:24 AM

Post by: Uniflow on October 09, 2012, 12:08:53 AM

Post by: Jeram on October 10, 2012, 12:42:24 AM

Make sure you dyno it against a bog stock YZ250. Turning the cylinder around with the crank still spinning forwards will cost HP

yes but as you told me, the straight exhaust is worth more than a few hp?

Post by: Jeram on October 10, 2012, 12:43:58 AM

* Lower CG will be achieved with the changes mentioned above.

how is this done without altering the counter-shaft height?

do you just lower the front of the engine and keep the sprocket where it is?

sounds like a plan though

Post by: TCI Performance on October 11, 2012, 02:42:44 AM

* I am not turning the cylinder around.

* Looking at a couple of different options for fuel injection but haven't decided just yet and it will not be used on this first build.

Post by: TCI Performance on October 23, 2012, 04:01:23 AM

In the meantime the engine has been completed and I am working on getting a new intake system for the initial build but if not I will go with standard carburetor and DFI after that.

Frame work is almost done and just need to CNC machine a few more pieces so I can get them all welded up at the same time.

I will post some pictures as I'm starting to put the bike back together. Hopefully I can complete and start testing within the next three to four weeks. Initially I wanted to be done by year end but even with the delay It looks more like mid November.

The next post should be more exciting as it will be including some pictures instead of just a rant. Thanks for being patience.

Post by: Stusmoke on October 23, 2012, 08:38:03 AM

Post by: TCI Performance on October 28, 2012, 02:47:38 PM

This is the most involved mod on the frame. The model is not the final design as it will need to be tweaked some but it's the starting point.

In order to establish the shape of this part I had to digitize the frame section of where the connection points are. This was done on one of my CNC's with a digitizing probe.

Moving along........

Post by: Stusmoke on November 01, 2012, 09:24:13 AM

Post by: TCI Performance on November 02, 2012, 03:38:47 PM

Wait if you're doing custom frame mods etc, will it be legal to race motocross? I thought there was some rule about the bike needing to be original in some areas, and I thought frame was one of them. Or is that just for factory riders or something?

Correct. For AMA sanctioned racing you can not alter the bikes frame other then what the rule book allows. The intent of this build is not for it to be AMA race legal but rather to continue the development of the two strokes by pairing them up with the latest technologies available. These bikes can be raced at many races just not the AMA Pro Sanctioned ones.

Post by: Stusmoke on November 02, 2012, 10:15:19 PM

Wait if you're doing custom frame mods etc, will it be legal to race motocross? I thought there was some rule about the bike needing to be original in some areas, and I thought frame was one of them. Or is that just for factory riders or something?

Correct. For AMA sanctioned racing you can not alter the bikes frame other then what the rule book allows. The intent of this build is not for it to be AMA race legal but rather to continue the development of the two strokes by pairing them up with the latest technologies available. These bikes can be raced at many races just not the AMA Pro Sanctioned ones.

Fair enough. Regardless I say Sod the AMA, if they hadn't been real di*ks we would still be racing and developing these machines.

Post by: bearorso on November 03, 2012, 05:58:45 PM

And the 'Y' piece design / modelling is a common thing used in putting a 2t engine into a 4t frame.

Is this really what this is?

An AFC type conversion to a twin spar frame?

Nothing wrong with that, at all, of course.

Mind you, I'd rather use the 05 / 13 Yamaha chassis with the back bone, single down tube into double cradle Aluminium frame if I were to do a 'different' AF when it comes to other engines - instead of the spar frames. Built with minimal parts and welding, using a variety of construction methods. It's a Very good frame. Both in terms of handling and durability. That has defied some 'experts' opinions about a 'conventional' type aluminium frame not being strong enough. Good design, can negate the need for large section tubing / large fabricated sections / large castings or forgings.

There is no inherent problem with the CS centre to SA pivot centre to rear axle centre with the YZ250. So I assume , if you are moving the engine, for whatever reason, you'll be making it so the CS position is in the same general area. When doing such a thing, you'd be mad not to add in a way of doing SA pivot adjustment / or CS / Engine placement adjustment, if you've made the effort to change so much of the engine mounting.

We may end up seeing production MX / Dirt Bikes being made to take an adjustable Swing arm Pivot 'chip', to allow some further suspension tuning. If mainly / only for marketing reasons, that few will choose to change. It's long been out there on several production road bikes.

Perhaps you will be doing some sort of anti torque set up - or simply a roller set up so as to not stuff up the suspension when the CS has been moved to a less than 'good' position, in the interests of wherever you intend to place / orient the engine?

A twin spar frame, with relocation of fuel tank and air box, could lend itself well to getting the 2t pipe out of the firing line of most of the (all too frequent) damage that they so easily get. That goal might be better served by movement of the engine, I think.

All questions / comments - not criticism.

It will be interesting to see what comes out of this.

Post by: TCI Performance on November 07, 2012, 04:12:25 AM

Post by: Lolerbabop on November 07, 2012, 08:15:36 AM

Post by: Stusmoke on November 07, 2012, 08:19:34 AM

God damnit man... Why aluminium?!

My thoughts exactly mate, I miss steel frames.

Post by: _X_ on November 07, 2012, 09:32:35 PM

Post by: TCI Performance on November 16, 2012, 06:48:47 AM

Got the frame welded up and started to re-assemble so I can place the engine in its correct position and fit the motor mounts for welding. There is quite a bit more to do mainly little stuff but that all adds up. The radiators need to be modified and new mounting points for the exhaust and electrical need to be welded up. One key thing in this build was to maintain the fit for aftermarket and OEM parts such as pipe, silencer, plastics and so on. That way if you where to crash and need a new pipe or plastics you just buy them from the store and bolt it on without modification

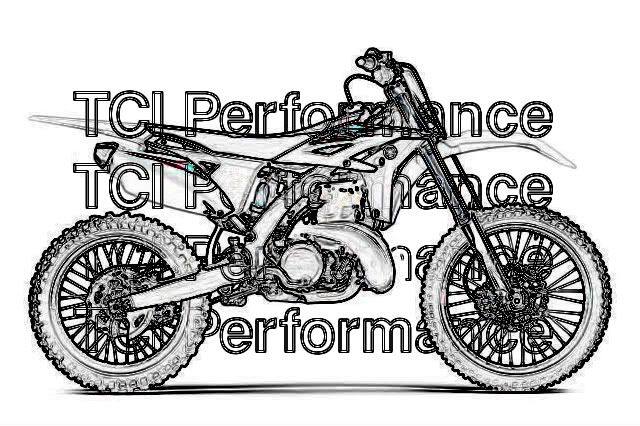

Below is a first look of what the bike is going to look like with the graphics.

Post by: shanes on November 16, 2012, 06:51:40 AM

Post by: TMKIWI on November 16, 2012, 06:55:26 AM

P.S. Looks nice.

Post by: Uniflow on November 16, 2012, 10:01:22 AM

Post by: Chrisshire on November 16, 2012, 10:47:06 AM

Just think how easy yamaha could turn these out

Post by: TCI Performance on November 17, 2012, 02:06:56 AM

What angle is the motor tilted back and is the CS in the same position.?

P.S. Looks nice.

Motor angle was changed some into a more neutral position to improve cornering but without affecting CS position.

Post by: Jeram on November 17, 2012, 04:28:56 AM

Post by: scotty dog on November 17, 2012, 12:09:43 PM

God damnit man... Why aluminium?!Why? Coz he can...

Post by: TCI Performance on November 17, 2012, 08:17:15 PM

Post by: gpnewhouse7 on November 17, 2012, 08:35:01 PM

Great bike though the bike looks amazing.

Post by: TCI Performance on November 17, 2012, 08:44:43 PM

Bike looks pretty sweet, just one question considering that the end result was basically just a YZ250 with YZF plastics why did you go the route of modifying the YZ frame rather than simply either buying the plastics conversion kit (either ufo or the one built in either sweden or finland, can't remember) or go the YZF YZ engine swap route? Would it not have been cheaper and still handle as well if not better than the home made frame you have made? Not saying your frame is bad but just that I would personally rather leave the frames to the professionals seen as there must be a million and one factors to consider when building one.

Great bike though the bike looks amazing.

It is built of a YZ250F frame. There are several reason for this conversion other then the obvious which is the looks and modernizing of the dated YZ250. We wanted to build something that will allow us to further develop new technologies into the bike (i.e. DFI and so on) and this build gives us what we need on order to do so. There are also several key technical changes we made to enhanced handling especially cornering that is not obvious to the eye.

Post by: gpnewhouse7 on November 17, 2012, 09:04:58 PM

Just interested in your plans.

Post by: scotty dog on November 19, 2012, 02:02:27 PM

Post by: nom de guerre on November 19, 2012, 04:46:33 PM

I may have missed this part, but what is the purpose of this build? Replication/sales? Personal fun? I would be pretty into this bike as a choice...

Post by: TCI Performance on November 20, 2012, 01:05:33 AM

Ahh okay, I thought you had modified the YZ frame. So is this just a test bed for future YZ modifications? Have you made any changes to the air intake? Have you thought any different suspension set ups or variable pipe set ups?

Just interested in your plans.

Yes this is our base platform build for the next phase of our future YZ250Ri project. In the meantime we will extensively test this build and make any necessary changes in order to get the best power and handling package. With this initial build we wanted to keep it as simple as possible and not introduce to many variables in order to properly evaluate the key changes made. Once this bike performs up to our likings we will start the new YZ250Ri project which it's main focus will be on the fuel injection.

Post by: TCI Performance on November 20, 2012, 01:30:15 AM

Nice.... Really nice. Where is the Smart Carb? Like the hydro clutch, but a little surprised you didn't try fitting a case slave. Great bike all in all.

I may have missed this part, but what is the purpose of this build? Replication/sales? Personal fun? I would be pretty into this bike as a choice...

Still waiting on the SmartCarb to arrive.

In short my passion of the sport and the 2 stroke is what started this project. That combined with my engineering knowledge and availability to produce pretty much anything I need within my company is what started it all. With all that in mind it was not started to sell units rather then develop something unique that can be ongoing. However I have been approached numerous times now about building them for people and I wouldn't mind once it is properly tested and performs to my standard. I am working with companies to see what can be done to get the components required in order to make this happen so that the bikes can be produced in whole or as a kit without costing an arm and a leg. That is and will be the challenge for now.

Post by: ford832 on November 20, 2012, 01:48:53 AM

Wow,nice job.

Wow,nice job.

Post by: luthier269 on November 20, 2012, 02:27:21 AM

Post by: nom de guerre on November 20, 2012, 03:47:54 AM

Thanks for the personal insight TCI... If this bike is just the beginning, I can't wait to see what is next!! I would be very interested in one of your bikes if you ever choose to produce anything for consumers.

Well done.

Post by: TCI Performance on November 20, 2012, 05:29:13 AM

What size rear tire is on it? And what size rim?

110/90-19 on a stock YZ250 rear wheel.

Post by: TMKIWI on November 20, 2012, 07:24:33 AM

Post by: bearorso on November 20, 2012, 03:23:12 PM

So Far.

Engine re-location - yes - 05 /13 YZ250 chassis to current model (?) YZF250 chassis.

Going by what you've said, the CS centre replicates the CS location of the original YZF engine.

You might have just been able to fit it straight in, with the centred hole case inserts. Perhaps, you may have had to make eccentric case inserts to achieve the CS location.

That might have resulted in the crank centre height being higher, or lower than it was on the 05 /13 frame. Certainly, the crank centre could be much lower than the OEM 4t engine.

With, or without a modified SA case insert, adjust ability for raising / lowering, the crank centre, could be achieved by 'slotted' lower forward engine mounts, and the front engine mounts - but that would be dodgy engineering, even with 'top hat' type insert washers. Better would be eccentric spacers into the cases - if you had enough meat / clearance to fit them. By machining the case insert hole larger, if the cases allow it, at the SA pivot point, you could possibly go to a larger eccentric 'difference'. All these adjustable mount points, could give you, at a rough guess, 4 x 4, to perhaps a 10 x 10mm (a very optimistic range) 'square' to move the engine around in. Off course, the head steady, would require adjustment potential , or a few different plates. From what little I can see, the lower and forward engine mounts, are 'plain' mounts, with no adjust ability - correct?

Something you could / should consider, is the use of engine mount plates - combined with a set of adjustable SA pivot case inserts. This would give much better engine placement adjustment potential, Plus, the ability to tune the feel of the chassis. Look to the variety of materials / thickness's of many mount plates used on a lot of the modern 4ts.

The last 2 AFs I made, were Gen 5 frames. A big improvement over the 4s. With those, I made the new, full cradle, to take removable plates. These were made for 2 friends of mine, who are / were Pro Level riders, that I've worked with for many years. So, they know how to develop / evaluate changes. And I know how to decipher their 'impressions and descriptions' of what a bike / each modification is doing. All up, I think we went through 10 sets of plates, in various materials, in various thickness's, and in various shapes. Each rider picked a different combination, as their 'best' setting. But, each rider gave me an equal rating of another set up as being their second pick. Engine mounting, can deliver considerable changes in the 'feel' and handling of a bike.

Something to be aware of, is to make the head stay mounts, so the top spars can still flex as intended - when viewed from above, the flex would be the spars widening. This is one of the major things that has been part of the evolution of previously far too rigid aluminium twin spar frames. This may be an improvement over the original aluminium back bone frame. You can right royally stuff up the handling with overly rigid head stay plates, and, indeed, create stress raisers, that will lead to spar cracking / breakage, if the bike is ridden Hard.

The fuel will be carried higher than the original 'saddle' type tank on the 05/13, with the existing YZF tank. Especially if you go to an aftermarket tank, to match the capacity of the original bike. You could, make a tank to make use of all that airspace that is available now that the 4t engine has been given the flick. Of course, the lower 2t engine, with no cams and valves, will have the advantage that the loss of those items (giro effect gone from those parts too), and engine height will deliver - plus the much lower carb, that will be a fair bit lighter than the 4ts FCR. The machined Smartcarb though, I'm pretty sure, will be heavier than the OEM carb. But, the , what I believe will be considerable benefits / improvements in the carburetion, will far outweigh a few ounces of added weight. I'm very impressed with the Smartcarb. Yes, without having used one - yet. With 'DFI' you could have a chance of fabricating a tank, to go into the area the carb currently sits - as a simple throttle valve / body, could be much smaller, and require little access.

I doubt that much weight savings will come from the engine swap , I think I've read that the YZ engine is a 54 / 56lb item. No effort has been put into the YZ engine to lighten it significantly in at least a decade, perhaps many more years than that. And, a conventional material chamber,and muffler, are often heavier than a full Ti 4t system. And, it would take the use of much thinner section / gauge aluminium frame parts, for the twin spar frame to be appreciably lighter than the incredibly simple / minimal parts count, 05 /13 back bone frame. There are far more sections / items to the twin spar frame, than the back bone frame. Perhaps, any real weight saving, may come from the swing arm, linkage and rear hub - the fitment of previous model YZF parts, has long been used to remove approximately 1.5 / 2lbs from the YZ250 2t. Plus the smaller tank / thinner plastics that 4ts have gone to.

Radiator re-location? Many would know of the Dubach Racing Radiator lowering kits - perhaps you might do that?

Or, relocating the radiators, better still, using a smaller single radiator, with a light weight fan, could offer a weight saving / useful weight re-distribution. Trials bikes use smaller radiators, some with fans, and believe me, that they are not moving through a stream of fresh air, and they can be under serious load, means they can get hotter than an MXer that is going relatively fast, with a good fresh air feed.

Perhaps you intend to eventually make use of the air space created by the lower engine, and put the exhaust in that spot? As noted on another thread here, 2ts Do Not require the stinger to be at the end of the convergent cone. Use of a long known technique for the stinger exit, could give you the room to have part of the chamber in the newly available air space above the 2t engine. The old 'Snake Pipe' build , at least part of it, could be put to use. And, you may minimise the 2t bugbear of easily damaged exhaust pipes.

You've currently used the logical idea of making the pipe and muffler mounts, to suit the OEM items - which should enable you to use existed aftermarket parts. That, I assume, would be the modifications to the subframe that I think I saw mentioned, though, you may also be considering the now common subframe lowering modifications that many do. A simple cut, shut and weld. Or, eventually, a monocoque construction subframe / airbox, in any number of materials

A mate of mine, early this year, put an YZ 2t into a 2012 YZF chassis - like what has been done here. And I'm sure there are quite a few around. His reportage of the difference between his expertly set up and fettled run of aluminium back bone framed YZs, has been "it's pretty much, much of a muchness". The key benefit, is he had something a bit different to what he had before, and even now, with a lot of development and set up, he feels that the original chassis, is in no way overshadowed by the YZF chassis. He, has, for quite a few years, run the YZF parts I mentioned above, that gave a useful weight loss.

Which brings me to the whole AF thing. An AF, can be made with tools as basic as a hacksaw, some files, and a drill and bits, with a TIG Machine to hand, or a TIG Welder that you can pay to do the 12 to say, 20 inches of welding. It's the most basic of 'engineering', and plenty of blokes in their garages do it - many, do a far better job than the companies that charge a small fortune for an AF conversion. Better tools and equipment, can make it easier to do, and, I favour replacement of the entire cradle over the cut and insert method, that is still done by 'noted' AF builders.

As for DFI - might I suggest you contact Athena, to see if they are intending to / have produced, one of their 'DFI" kits for the YZ. The upwardly pointed injector, high on the side of the barrel, is an elegant solution / alternative to the 'conventional DFI' set ups that 4ts and, I think, Evinrude / BRP - Rotax use - much of it licensed from Orbital. Athena's 'DFI' makes use of a 2ts flow patterns, without the need for complicated, heavy , expensive set ups that have been the norm. It also, is the sort of thing, that a competent engineer, could do themselves. That some regard a 'from above / in head DFI' as the Only DFI, is only through the fact that that has been the most common DFI 'solution'. And their lack imagination.

But, to repeat, we've an AF conversion here.

So Far.

I hope to see the results of further development, that will set this bike apart from a 'run of the mill' AF conversion.

Good luck to TCR in their / his endeavour.

Post by: TCI Performance on November 20, 2012, 05:16:52 PM

Can you send me or post up some pictures of your conversions so I can evaluate them also? I have only seen pictures of the MPS bikes and would like to see what others have come up with to compliment them on their efforts to continue the quest of modern 2-strokes.

Have a great day and thanks again for your in depth reply......oh and it's TCI not TCR.

Post by: citabjockey on November 20, 2012, 07:57:41 PM

All that said... Cool looking bike. Can't wait to read about the DFI development!

Post by: twosmoke595 on November 20, 2012, 08:19:52 PM

TCI - don't worry about beroso's dissertation's tone. He does this everytime he comments on a custom build. That said he sure does seem to know what he is talking about. Also, it did not sound to me like a downer review of your work to me (but I have seen his posts before).

All that said... Cool looking bike. Can't wait to read about the DFI development!

same, i didnt see any negativity in his post, very informative, i think he was just adding onto your ideas as well as telling you his own

Post by: _X_ on November 20, 2012, 09:18:29 PM

Post by: TCI Performance on November 20, 2012, 10:51:01 PM

That's the reason I asked about some pictures of his own doings because I love seeing other peoples approaches. I am pretty new on here so I don't know if he has posted pictures in the past or not but if he did please post a link.

The problem is that some of them talk a good story but they can't back it up. Not saying that bearorso is that type of person especially since he sounds like someone that knows what he is talking about. But like I always say.....seeing is believing.

For me personally.......I applaud anyone trying to keep developing the 2-Strokes no matter if he is working out of a shed in the backyard or has a reputable company like myself.

Again our core business is not building bikes.....but it's the racing experience combined with the passion and knowledge that drives me personally to spend the time, effort and money to hopefully build the baddest looking most technologically advanced 2-Stroke to date. It's a dream of mine and I am going after it and nobody is going to change that.

Post by: twosmoke595 on November 20, 2012, 11:00:27 PM

Don't get me wrong....I agree with a lot of what he posted and therefore know he has good knowledge about this subject.

That's the reason I asked about some pictures of his own doings because I love seeing other peoples approaches. I am pretty new on here so I don't know if he has posted pictures in the past or not but if he did please post a link.

The problem is that some of them talk a good story but they can't back it up. Not saying that bearorso is that type of person especially since he sounds like someone that knows what he is talking about. But like I always say.....seeing is believing.

For me personally.......I applaud anyone trying to keep developing the 2-Strokes no matter if he is working out of a shed in the backyard or has a reputable company like myself.

Again our core business is not building bikes.....but it's the racing experience combined with the passion and knowledge that drives me personally to spend the time, effort and money to hopefully build the baddest looking most technologically advanced 2-Stroke to date. It's a dream of mine and I am going after it and nobody is going to change that.

you have our support

Post by: 2T Institute on November 21, 2012, 06:45:59 AM

Don't get me wrong....I agree with a lot of what he posted and therefore know he has good knowledge about this subject.

That's the reason I asked about some pictures of his own doings because I love seeing other peoples approaches. I am pretty new on here so I don't know if he has posted pictures in the past or not but if he did please post a link.

The problem is that some of them talk a good story but they can't back it up. Not saying that bearorso is that type of person especially since he sounds like someone that knows what he is talking about. But like I always say.....seeing is believing.

For me personally.......I applaud anyone trying to keep developing the 2-Strokes no matter if he is working out of a shed in the backyard or has a reputable company like myself.

Again our core business is not building bikes.....but it's the racing experience combined with the passion and knowledge that drives me personally to spend the time, effort and money to hopefully build the baddest looking most technologically advanced 2-Stroke to date. It's a dream of mine and I am going after it and nobody is going to change that.

So what are we seeing? A YZ250 with a sticker kit and a slightly modified frame. When is all the technology going to be applied?

Post by: factoryX on November 21, 2012, 08:34:10 AM

Post by: Jeram on November 21, 2012, 11:19:50 AM

I will withold any other judgements untill the "technical improvements" are completed at some point in the future.

Post by: Markopolo400 on November 21, 2012, 10:38:46 PM

Post by: factoryX on November 22, 2012, 12:53:56 AM

Post by: TCI Performance on November 25, 2012, 03:53:31 AM

Post by: Uniflow on November 25, 2012, 05:20:40 AM

Post by: Uniflow on November 25, 2012, 11:01:47 PM

Post by: Uniflow on November 25, 2012, 11:11:41 PM

Post by: TCI Performance on November 26, 2012, 06:03:34 AM

In your case you didn't bother modifying or heat treating after modification?

I know of several guys that have built AF conversions and said that they don't heat treat afterwards. Some say they just weld small sections at a time thus preventing the frame from getting too hot. The fact is that when you weld a section of the frame you are bringing the material to melting temperature thus altering it's temper some. Because the frame is not kept at that temperature for a long period of time it will not get back to T0 but certainly loos some of it's strength which can cause stress fractures down the road followed by complete frame failures. Not a risk I'm willing to take.

Post by: Uniflow on November 26, 2012, 07:49:41 AM

I've seen too many alloy frame / weld disasters, It must be heat treated afterwards.

Post by: SachsGS on November 26, 2012, 03:10:09 PM

Post by: Lolerbabop on November 26, 2012, 10:16:05 PM

Post by: TCI Performance on November 27, 2012, 03:06:42 AM

Just waiting to finish up some loose ends on the bike so we can get started with testing.

Post by: Uniflow on November 27, 2012, 06:29:48 AM

Post by: dogger315 on November 27, 2012, 03:11:58 PM

Quote

So how did you heat treat the frame without the rest of it distorting? Usually heat treat then machine.Interesting discussion about heat treating. I'm not sure what alloy Yamaha uses for their frames, but the Japanese

manufacturers don't stray too far from one another. Honda uses 7075-0 for their frames. This alloy has a tensile

strength of 40,000 psi which is about the same as 6061-T6. One of the bennies of using 7075 in an untempered

state, is you don't have to worry about strength loss due to weld repairs or modifications. It is generally accepted

when welding Aluminum alloy, that the area adjacent to the weld will have a "0" temper. That's a considerable loss

of strength from a "T6" state, but no loss from a "0" state.

Some of the AF conversions are being done by people that have little to no knowledge of materials and/or welding

skills. Trying to weld 6061 -T6 pieces to a 7075-0 frame is a recipe for disaster if the proper post weld processes

aren't followed.

Long story short, I can weld away on my 7075-0 frame without worrying about heat treating afterward. If you used

7075-0 alloy for the replacement parts, I bet the same is true for that Yamaha.

dogger

Post by: TCI Performance on November 27, 2012, 03:18:25 PM

We use zippy ties for those things Ha Ha.

Hmmmm......remind me not to try one of your bikes LOL

Post by: Uniflow on November 28, 2012, 12:51:43 AM

Post by: cnrcpla on November 28, 2012, 01:28:24 AM

Quote

We use zippy ties for those things Ha Ha.They are very handy miles away from home in the woods

Hmmmm......remind me not to try one of your bikes LOL

I used one once in place of a tie-rod carter-pin for a banshee after I hit a tree. It actually held up for a while. Obviously I replaced that part, but they serve a good purpose, for stitching plastics as well.

I used one once in place of a tie-rod carter-pin for a banshee after I hit a tree. It actually held up for a while. Obviously I replaced that part, but they serve a good purpose, for stitching plastics as well.

Post by: Uniflow on November 28, 2012, 01:51:06 AM

Post by: bearorso on November 28, 2012, 09:03:25 AM

QuoteSo how did you heat treat the frame without the rest of it distorting? Usually heat treat then machine.Interesting discussion about heat treating. I'm not sure what alloy Yamaha uses for their frames, but the Japanese

manufacturers don't stray too far from one another. Honda uses 7075-0 for their frames. This alloy has a tensile

strength of 40,000 psi which is about the same as 6061-T6. One of the bennies of using 7075 in an untempered

state, is you don't have to worry about strength loss due to weld repairs or modifications. It is generally accepted

when welding Aluminum alloy, that the area adjacent to the weld will have a "0" temper. That's a considerable loss

of strength from a "T6" state, but no loss from a "0" state.

Some of the AF conversions are being done by people that have little to no knowledge of materials and/or welding

skills. Trying to weld 6061 -T6 pieces to a 7075-0 frame is a recipe for disaster if the proper post weld processes

aren't followed.

Long story short, I can weld away on my 7075-0 frame without worrying about heat treating afterward. If you used

7075-0 alloy for the replacement parts, I bet the same is true for that Yamaha.

dogger

7075 - No.

Not in use in the welded structure that is the frame. Of Any motorcycle that I am aware of. But, there may be 'some' out there............

I assume you are the 'Dogger' I've had P.M contact with in the past?

Certainly, Most of the materials used in Japanese frame making Will be a variant of 7*** series materials. Though, there will be a mixture - plenty will have some 6*** and / or 5*** series materials. Generally, plate, and 'std' section type tube shapes. And 'other' materials.

The majority of Aluminium used in many manufacturers, especially the Japanese, will be a proprietary 7*** 'Mix' that will not be disclosed. Indeed, many 'mixes' will not appear on Any standard aluminium materials 'alloying' listings.

Some (most) 7*** materials have been specifically developed to not require heat treatment after welding - the natural 'ageing properties' of the materials are accelerated over other aluminium alloys. So, they will regain most of the base metals properties without any 'heat treatment', or artificial ageing. Some can be subjected to post weld treatment, some, not (goes to show, 'hard and fast rules' are not so 'hard and fast', often re 7*** being listed as heat treatable, as is 2***, and 6****. Conversely, you have the Non Heat treatable materials, that some of which, Can be Heat Treated - notably some 4*** and 5*** series - more on that further on).

7005 has become perhaps the most common, relatively inexpensive aluminium alloy for welded structures - most notable bicycle frames. The material itself is affordable, and, it's properties of reconstitution of base material specs / age hardening, present a Very useful savings in not having to heat treat / manipulate the frames after welding.

It's thought, by many of us small fabricators / frame makers, that much of the proprietary 'mixes' of Japanese and European / British motorcycles, Are 7020, Or Near To 7020 - a lovely material, which the Poms make great use of.

7075 is one of the aluminium alloys that is generally described as 'un-weldable'. Well, it's surely weldable, but surely a great way to produce a 'widow maker' of a structure. Be it welded without further heat treatment, or with further heat treatment. Playing with 7075, in welded structures / fitments, is like Russian Roulette - with All six barrels loaded.

Some of the best information, put in layman's terms, with regards to welding, is to be found on various welding machinery companies sites, such as Lincoln, miller and ESAB.

The ESAB one is very easily used and understood:

http://www.esabna.com/us/en/education/knowledge/qa/index.cfm

It may behoove some to read the above short and simple - in scholarly / engineering terms - link.

With my reference to 'hard and fast rules'. They are often broken. Many, here if you are into bicycles, will see often frame specs advertised, especially with American made frames, of the frame being made from 6061 T6 Tubing. Now, often, that means exactly that, and Only that. The frames Are made of 6061 T6 tubing, but they are Not solution heat treated after welding, or artifically aged. Indeed, it would be better, in terms of cost, for the frames to be made from 6061 - 0 / annealed tubing, Then have them solution heat treated and aged. Why pay for more expensive tube, that will then need to be brought back to 0 - annealed condition, to then be solution heat treated, and artificially aged? Most of the '6061 T6 Tubed' frames, are just welded up, being 'tacked only' in the jigs, welded fully and then, twisted / manipulated to straightness. The manufacturers sure can't be accused of lying. This can be got away with, by various methods - overbuilding - generally by much thicker butt ends than really are required, or larger sized tubing, staged welding techniques and so on.

My aluminium swing-arms and frames, are welded fully 'in jig', so no distortion happens - and / or, the known distortion is accounted for in the materials and jigging. As well as timed / staged weld patterns. Nothing of mine, requires manipulation - bending and subsequent weakening - or machining, after the structure is 'un-jigged'. I then, artificially age the structures in 'jigs', made for this purpose.

Some, very light weight / minimal design items I make, Are fully solution heat treated and artificially aged - or simply time aged, if the material is better suited to that. 'Free standing' (dirt bike type, generally) Aluminium Swing Arms, for example. And my very thin sheet construction swing arms. And, when my swing arms Are heat treated, it is done, in 'jigs' specifically made for the purpose. My triangulated swing arms - generally, no, they are subjected to the process outlined in the previous paragraph. Unless, they are outrageously light gauge in their construction.

Frames such as Cannondales 6061 tubed items, that are built with their 'multiple pass welding' that is then linished to form the large radius joints / 'non joints' (to many of the public's perceptions) are Almost always fully solution heat treated and artificially aged after welding. As the massive heat build up from multiple passes and wide fusion zones / Haze areas, really dictates that it be done. As well as many stamped type frames - the stamping / pressings requiring the sheet to be in 0 / annealed condition.

When I see the various 'commercial' AF builders list the frames as 'heat treated', I regard such claims with a Very Large grain of salt. I seriously doubt that they are brought back to 0 / annealed, then solution heat treated and artificially aged - with the required manipulation / machining of the frames between steps. Unless, of course, they have seriously substantial heat treatment jigs made and in use.

When I have made full new cradles - which is all I've done since the very first Gen 1s I did in '97 - I've heat treated the cradles, be they just bent tubing, or my favourite indulgence, 'welded plate' cradles, both types with the mounts attached to them, prior to heat treatment. Then, carefully staged welding patterns, with optimum timed welds, jigging, and large contact areas, are used for the cradle fitment. No post welding heat treatment required. I've never had a failure, in 16 years of CR AF conversions. And far longer when it comes to various other TZ / RG, GSXR etc hybrids.

Further to my mentioning of 'hard and fast rules', if you read that ESAB listing, you'll see various 'contradictions' regarding welding rods / filler material. You'll see that the most common filler materials / rods - 4043 and 5356, come into the 'Non Heat Treatable category of materials. Yet, they can, and Are used in weldments that are to be heat treated. Weird, isn't it?

I don't use 4043 much at all, most of what I do, I use 5356. Both rods 'base alloying', being of Non Heat Treatable alloys. Yet, they present No problems with subsequent heat treatment of a build. Weird, again, according to the rules.

I Do stock, And use, another 3 variations of both 4*** and 5*** series rods for special purposes. And, quite often, a sheet or tube (when dealing with frame repairs - from written off frames of the same type) of specific material, will be guillotined / cut up, to give me a definitive, known source of welding rod. A few of the 'anomalies' amongst welding rods are mentioned / explained in the ESAB listing. As I said, it's a very useful thing for the layman, And professionals, alike. I have many types of such listings kept handy - near materials racks, and various machines / work benches in my workshop. Hey, I'm getting old, I'm Very busy, and I know it's easy to F*** up, even (or perhaps because of) my decades of experience. And, I spend much of my time away from the workshop, in the halls of education, lately. So, I am doubly cautious when I do get back into my workshop.

Yes, my postings may read as treatises, at times, but I try to make them accurate, and informative. I'm not here, or on any sites to make money - I am trying to help people with their projects and impart a bit of my knowledge, so they don't stuff up. There's been a few people, that I've helped - or who have read my postings, who have gone on to make money using my advice / ideas. Fair enough, when I've put it in the public arena. Not fair enough, when it's been in private, and a few p***s have claimed things as their own, to then make money off.

Dogger, I seriously doubt your donor frames are 7075 Aluminium Alloy. Perhaps you've just made a 'typo'?

Post by: 2T Institute on November 28, 2012, 09:50:02 AM

Post by: bearorso on November 28, 2012, 10:19:08 AM

Thank you Debbie Downer for you thorough evaluation of our build. Just to be clear we didn't want or was it our intention to build a full on one off works bike, we leave that up to people like yourself. Surely there are plenty of people out there building conversions........never said we where the first ones. However there is more to it than just throwing a motor into a different frame but I'm sure you are fully aware of that.

Can you send me or post up some pictures of your conversions so I can evaluate them also? I have only seen pictures of the MPS bikes and would like to see what others have come up with to compliment them on their efforts to continue the quest of modern 2-strokes.

Have a great day and thanks again for your in depth reply......oh and it's TCI not TCR.

Well, I made a typo on your company (?) name. Mea Culpa.

I suggest you re read the paragraphs between the first 2 short paragraphs, and the last 4 short paragraphs.

If your comprehension levels are reasonable, you will see some questioning, and some advice / suggestions.

No criticism.

I suggest you have a 'cup of concrete and harden the F*** up'.

You've turned up with the announcement of a Big Project, not having appeared here before (if I'm wrong with that, I apologise).

And, so far we have an AF. As a few others, that don't seem to automatically deify you, have noted. Some, have seemed to deify you - perhaps that's what you're after?

There's a few to many Very Clever people here, to just line up and genuflect to your 'greatness'. You are the one that seems to be touting your expertise and achievements - without any 'evidence' of it. Not that

i had required that of you. Grow up, and harden the f*** up, as I said, mate.

We've even got that most clever of 'mad scientists' - a Kiwi, in the form of Uniflow here. If there's one mob that may be able to outdo us Aussies in making a space shuttle out of 'found items', hard work and ingenuity, it's those bloody Kiwis. Mongrels, the lot of them.

Hi there, Uniflow - I'm Very interested in your engine project. I'm fairly engine 'educated', but I will always defer to those that appear to know far more than I, and who are going to do something with an engine project that I would not be inclined to attempt. On Ya, ya mad bastard!

Hi there, Uniflow - I'm Very interested in your engine project. I'm fairly engine 'educated', but I will always defer to those that appear to know far more than I, and who are going to do something with an engine project that I would not be inclined to attempt. On Ya, ya mad bastard!Now, some of the above IS ripping into you. My posting you 'whined' about, was not.

So, with the AF to AF conversion: using what you've written - that you've duplicated the original position of the CS (I assume the position of the YZF engines CS), and, I assume, the original centred hole case adaptors of the YZ 2t engine, the position of the engine, is set by that. I can't see much innovation or thought with that said positioning - but, of course, you Have repositioned the engine from one frame to another. There's an example of how you can, and will, deservedly be questioned.

I do hope that you have thoroughly examined the gauge / strength of the section of down tube you have attached the machined 'Y' piece to - Down tubes generally are quite thin, away from their origininal 'Y' section joining area, and, with the section / rigidity I can see with your 'Y' , I see a potentially very real stress concentration point, between the 'Y' and the original down-tube reinforcement. No room for 'give', basically. Now, there's a little bit of criticism for you, but, I'd call it constructive criticism.

As I wrote. I await the true innovation that I hope, is to come.

WTFactoryX :

A side note - that I alluded to in the posting, is the position of the tank / pipe etc. - you can go too far with the lowering of the centre of gravity. A classic is the 'upside down' NSR 500 that Honda tried with Freddie Spencer. Pipe over the engine, tank below the engine . Having the C of G of that low, / the weight of the fuel load so low, made the force vectors going into the front tyre contact patch very horizontally oriented - thus 'Pushing" the front wheel. The bike was a pig of a thing and very dangerous. It drove FS back to the lovely little triple. It lost far to much of the needed 'Push Down into the ground' forces that give grip. And, too low a centre of gravity, can make a bike unstable, and difficult to 'tilt' / 'roll', so to speak , despite what people imagine. The Sloper Bergs had that as a bit of their 'difference' in feel, as well as their 'Yawing'. Weight Transfer, can be taken too far / lessened too much.

I have the feeling, that TCI, would be better to fit the pipe etc, between the engine and tank - though, any extra capacity / same capacity may be worthwhile compressed down into any space left after the positioning of the pipe, above the pipe. When the 'tank in the air-box position' was tried - notably with the Suzuki that Mark Barnett (for you US blokes reference) rode for a short while - it was just a step to far - on a simple and light weight 2t. Yes, there Are rear tanks, but they are far higher than a 'down by the case and SA pivot' type. Tank locations much like that, work well on Superbikes / Moto GP bikes, due to the sheer mass of the engines, and their engine architecture - very forward orientated.

So, back to TCI.

As I said, I await further 'developments' of your project. If you can't handle some questioning, I suggest you've made the wrong decision in placing your 'project' here. So far, I see an AF. and a fair bit of self aggrandisement. But, everything has a starting point.

Go to it.

I hope you can achieve your goals.

I, and I'm sure many others, are hoping to be impressed. And, indeed, wish you well in your efforts.

Post by: bearorso on November 28, 2012, 10:22:08 AM

That's a awesome write up.

Or, perhaps, just an old bastard rambling along.

Post by: Jeram on November 28, 2012, 12:11:22 PM

That's a awesome write up.

Or, perhaps, just an old bastard rambling along.

perhaps both.

(they're not mutually exclusive)

hehe

Post by: dogger315 on November 28, 2012, 04:31:46 PM

Quote

I seriously doubt your donor frames are 7075 Aluminium Alloy. Perhaps you've just made a 'typo'?You're right, I should have stated the material was/is 70XX-0 Aluminum alloy, instead. The alloy is proprietary like you said,

and specifically designed to Honda's specifications. Like I said before, I would be very surprised if all the "big four" didn't use

something similar, and from the same sources.

If you know the right people, you can get the alloy from these folks: AISIN KEIKINZOKU CO. They are one of the vendor that

supplies Honda.

Quote

I assume you are the 'Dogger' I've had P.M contact with in the past?No pm contact, but I have read your post on other sites.

Thanks for the informative response, always good to learn new information and consider different angles.

dogger

Post by: nom de guerre on November 28, 2012, 09:14:23 PM

Post by: _X_ on November 28, 2012, 09:30:07 PM

Post by: TCI Performance on January 11, 2013, 05:18:08 PM

APT SmartCarb works awesome so far and we are heading onto the Dyno next week for data.

More info to follow within the next couple of weeks.

Post by: citabjockey on January 11, 2013, 05:59:19 PM

Bike looks great. Looking forwar to more test results. Is it being raced now?

Post by: oppenheimer77us on January 11, 2013, 11:31:17 PM

Post by: TCI Performance on January 14, 2013, 03:37:52 AM

I have read elsewhere that the apt carb will fill crankcase pronto with the bike on its side. Have you found this to be the case?

Bike looks great. Looking forwar to more test results. Is it being raced now?

So far we haven't had any problems with the carb filling up the crankcase and have only good things to report about the SmartCarb.

We had a few different riders take it for a first impression ride and they all felt the bike had very good power with great throttle response.

This week we will test the bike on the Dyno back to back against the stock PWK carb. This should confirm what we feel on the track so far.

A more detailed write up will follow after we complete the Dyno testing. The bike will be raced after we have the magazine tests behind us.

Post by: Stusmoke on January 14, 2013, 05:05:11 AM

I have read elsewhere that the apt carb will fill crankcase pronto with the bike on its side. Have you found this to be the case?

Bike looks great. Looking forwar to more test results. Is it being raced now?

So far we haven't had any problems with the carb filling up the crankcase and have only good things to report about the SmartCarb.

We had a few different riders take it for a first impression ride and they all felt the bike had very good power with great throttle response.

This week we will test the bike on the Dyno back to back against the stock PWK carb. This should confirm what we feel on the track so far.

A more detailed write up will follow after we complete the Dyno testing. The bike will be raced after we have the magazine tests behind us.

If you don't mind me asking, how much did the smart carb cost?

I can't wait for this thing to be finished. This is the motocross bike Yamaha should be making.

Post by: citabjockey on January 14, 2013, 02:54:53 PM

Post by: JRod4928 on January 14, 2013, 03:07:26 PM

Post by: ford832 on January 14, 2013, 03:13:36 PM

Can I have it?

Can I have it?

Post by: TCI Performance on January 18, 2013, 04:19:37 PM

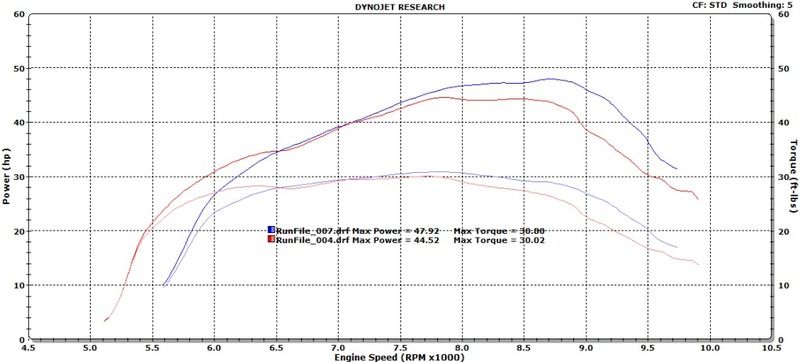

We have been testing the bike on the track the last couple of weeks and were noticing that the main difference between the stock carb and ATP SmartCarb was that we could keep the bike in gear longer.We felt that it would still pull hard when we would had to shift with the stock setup. Even though the stock carb comes on quicker we had absolutely no problem pulling out of the corners with a smooth power delivery which made it more like a 4-stroke type power but then pulled very strong up close to the 9K rpm range . Also we have noticed that we are using less fuel with the SmartCarb over stock. We haven't measured exact values as of yet but will in the next few test sessions.

The below Dyno run confirms what we felt.

PLEASE NOT THAT THIS DYNO RUN WAS NOT DONE TO SHOW HOW MUCH PEAK HP OR TORQUE THE ENGINE PRODUCES BUT RATHER THE PURE DIFFERENCE BETWEEN A PROPERLY TUNED STOCK AND ATP SMARTCARB BACK TO BACK WITH THE SAME BIKE SETUP.

Blue = 38mm SmartCarb

Red = Stock 38mm PWK

Thank you to Crower Performance for conducting the test for us.

In the next few weeks we will do more track testing to fine tune the suspension and have a few pro level as well as intermediate level riders give some feedback on the entire bike.

So far we have been very pleased with the bike and it is time to let independent guys and magazines test it for additional feedback.

We are planning on running the bike in a few selected races like the 2-Stroke Nationals and so on.

Post by: TCI Performance on January 18, 2013, 04:47:32 PM

http://www.motovationsports.com/2013/01/18/tci-performance/

Thank you Steve Emter of Motovation Sports

Post by: twosmoke595 on January 18, 2013, 07:43:23 PM

that's some decent numbers with just a carb swap

Post by: Stusmoke on January 18, 2013, 09:39:57 PM

Thanks for the dyno information. I'll definitely be buying one

Post by: 2T Institute on January 18, 2013, 09:50:25 PM

Blue = 38mm SmartCarb

Red = Stock 38mm PWK

You have just swapped bottom end for top end. Some work on the PWK powerjet switching/ignition would match that over rev.

Post by: ford832 on January 18, 2013, 11:28:13 PM

Post by: scotty dog on January 19, 2013, 09:57:52 PM

Post by: Watson777 on January 20, 2013, 02:28:29 AM

Post by: TCI Performance on January 20, 2013, 04:05:43 AM

Post by: riffraff on January 20, 2013, 04:10:06 AM

Post by: TMKIWI on January 20, 2013, 05:41:52 AM

I like... I LIKE! I want one of each

X 1,000,000.

I think the 1 with wheels will be cheaper to maintain.

Post by: shanes on January 20, 2013, 06:21:03 AM

I like... I LIKE! I want one of each

X 1,000,000.

I think the 1 with wheels will be cheaper to maintain.

i would dial in as much rebound as possible to the one without wheels so she gives you a real bumpy ride :-}}}

jokes aside great job with the photo shoot having a very classy but sexy model looks so much better than the cheap looking strippers a lot tend to use .

put me down for a poster you you print them up

Post by: Stusmoke on January 20, 2013, 09:20:25 AM

Post by: scotty dog on January 20, 2013, 01:33:23 PM

I'll take five of each please. Haaaaaaaaawwwwwwwt

Post by: scotty dog on January 20, 2013, 01:38:58 PM

Oh my god! Do you even understand how badly i want to ride that bike!!!! I would cry if I could afford to build that!you would be a good candidate for a test ride Watson, bein a forum member n all

Post by: Jeram on January 21, 2013, 04:23:48 AM

Blue = 38mm SmartCarb

Red = Stock 38mm PWK

You have just swapped bottom end for top end. Some work on the PWK powerjet switching/ignition would match that over rev.

I agree if your yz is making peak power at 8000rpm with the pwk then something isn't right

Post by: Stusmoke on February 09, 2013, 10:44:21 PM

Post by: TMKIWI on February 10, 2013, 04:48:14 AM

Yeah I think I'll pass on that too... I'd rather have first crack at both.

I think both would spit you off leaving you scared for life stu.

Post by: riffraff on February 10, 2013, 05:41:15 AM

Yeah I think I'll pass on that too... I'd rather have first crack at both.

I think both would spit you off leaving you scared for life stu.

guaranteed one of them would

Post by: Stusmoke on February 10, 2013, 11:40:30 AM

Yeah I think I'll pass on that too... I'd rather have first crack at both.

I think both would spit you off leaving you scared for life stu.

guaranteed one of them would

I'm not sure if I would rather take it as a badhanded slap to my ladying skills, or my riding skills... Let me think it over

On the otherhand, I think TMKIWI is on the moeny