Post by: Marco810 on April 08, 2012, 04:09:44 PM

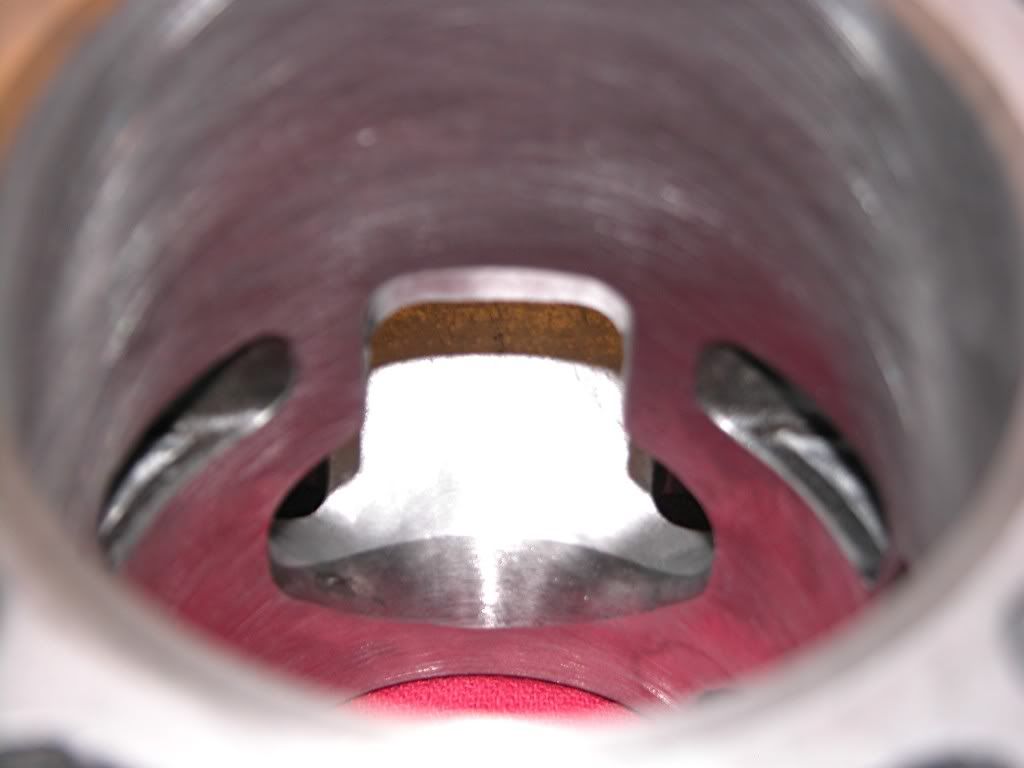

Jug before i sent it off. some chips in the plating. was the first time i had this engine apart, so go figures its been neglected

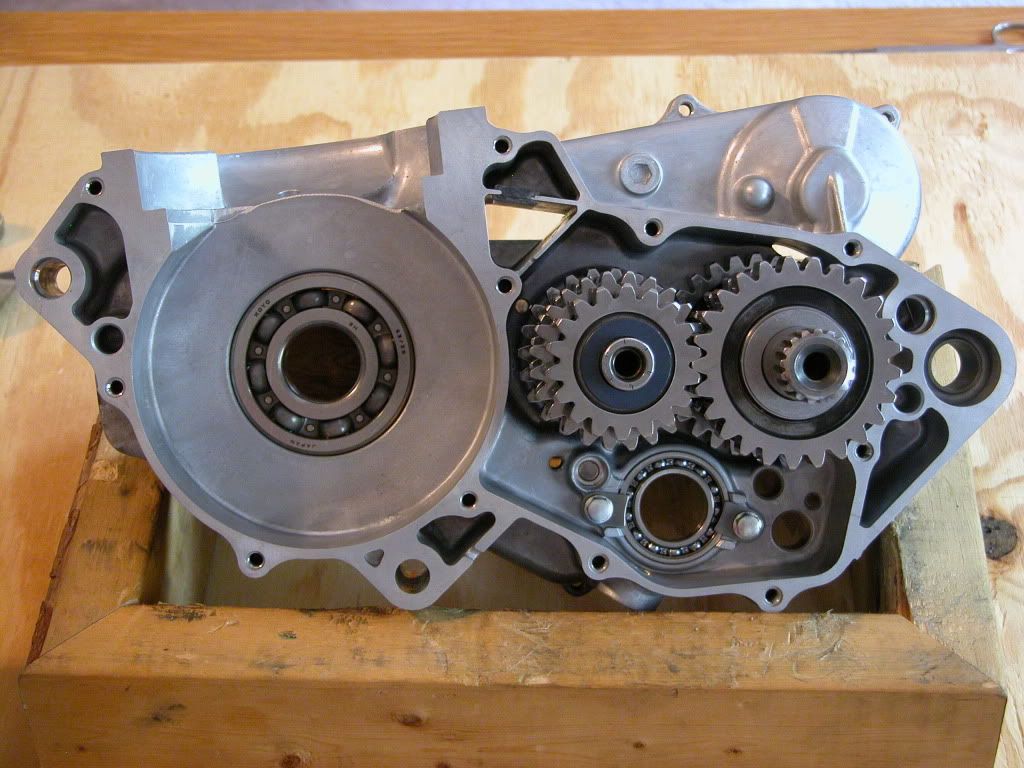

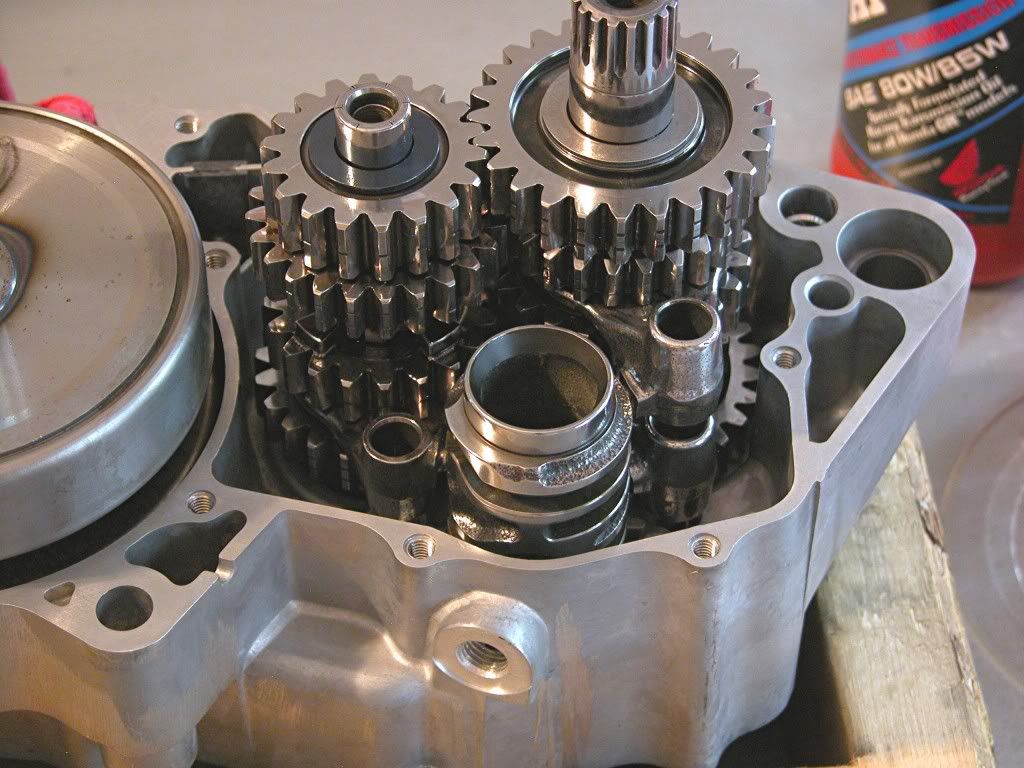

Gathering of parts. still need to send my crank off for rebuild

Post by: cnrcpla on April 08, 2012, 05:46:23 PM

Post by: Recovered on April 08, 2012, 07:13:35 PM

Post by: cnrcpla on April 08, 2012, 11:09:27 PM

Post by: Marco810 on April 09, 2012, 01:12:47 AM

Oh ok. That makes sense. With the lighter weight that monster is going to hit like a beast... Videos?

Ive been wanting to get a Gopro for some time now..

Another thing with the 250 ignition is a more aggressive ignition curve. Thinking about a Lectron, anyone have experience with them?

Post by: Recovered on April 09, 2012, 01:27:07 AM

Post by: cnrcpla on April 09, 2012, 01:41:21 AM

Quote

Insert QuoteI have seen them for that price everywhere. And every time I walk by them I cant help but wonder what else I could buy for that price that would actually benefit me or my bike

i dont think you can go wrong walking into target and buying the gopro for 299.

SO instead I made a free mounting piece for my helmet or bars that holds any camera. (I just have to test it out)

SO instead I made a free mounting piece for my helmet or bars that holds any camera. (I just have to test it out)

Post by: Marco810 on April 09, 2012, 02:19:05 AM

Post by: cnrcpla on April 09, 2012, 12:16:32 PM

Post by: Recovered on April 09, 2012, 02:45:03 PM

Post by: SachsGS on April 09, 2012, 03:36:22 PM

I didn't know Lectron was still in business.They were a popular conversion for piston port/non reed bikes back in the 70's and worked quite well.

Post by: dogger315 on April 09, 2012, 04:43:22 PM

Quote

porting, 250 ignition, 41mm pwk (pump gas), and what ever else i can think ofI recently built a CR500 engine specifically for MX so our two goals are miles apart, but some

of the mods I made would be beneficial for a dune bike. For the top end, I had Eric Gorr do the

port and head work. He recommended a Wiseco piston because it is more durable than the

cast OE. I sent that piston and crank assembly to Crank Works for balancing at 6-8000 rpm

which is the meat of the powerband for a 500. I also had all of the rotational internals REMed.

This process greatly reduces friction and heat and improves clutch action and shifting. I also

installed a VForce 3 reed and a 2000 CR250 ignition with a Vortex IC. IMO, all of these changes

would also be beneficial to a big power, top end engine.

Here's a couple of pictures of my engine. I look forward to following your build and to see what

you ultimately come up with.

Quote

With the lighter weight that monster is going to hit like a beastActually, the bulk of the weight (crankshaft), is still there. The smaller rotor helps with the gyro

effect and makes the bike feel lighter and more manageable in the air and in corners. The biggest

gain is going from an analog to a digital ignition and the ability to program the mapping. You can

really increase the hit (if you're a sadist), or virtually eliminate it.

dogger

Post by: Marco810 on April 10, 2012, 02:45:11 AM

Are you building a drag racer?

I didn't know Lectron was still in business.They were a popular conversion for piston port/non reed bikes back in the 70's and worked quite well.

Drag/play bike. I may just stick with the PWK, from what ive researched Lectron is more of a wide open only carb

Quoteporting, 250 ignition, 41mm pwk (pump gas), and what ever else i can think ofI recently built a CR500 engine specifically for MX so our two goals are miles apart, but some

of the mods I made would be beneficial for a dune bike. For the top end, I had Eric Gorr do the

port and head work. He recommended a Wiseco piston because it is more durable than the

cast OE. I sent that piston and crank assembly to Crank Works for balancing at 6-8000 rpm

which is the meat of the powerband for a 500. I also had all of the rotational internals REMed.

This process greatly reduces friction and heat and improves clutch action and shifting. I also

installed a VForce 3 reed and a 2000 CR250 ignition with a Vortex IC. IMO, all of these changes

would also be beneficial to a big power, top end engine.

Here's a couple of pictures of my engine. I look forward to following your build and to see what

you ultimately come up with.QuoteWith the lighter weight that monster is going to hit like a beastActually, the bulk of the weight (crankshaft), is still there. The smaller rotor helps with the gyro

effect and makes the bike feel lighter and more manageable in the air and in corners. The biggest

gain is going from an analog to a digital ignition and the ability to program the mapping. You can

really increase the hit (if you're a sadist), or virtually eliminate it.

dogger

Looks great Dogger. Not sure if CR's benefit from piston windowing but it would be worth looking into. People claim a easy +2hp for the KX with a piston window.

Was trying to decide on weather or not ill get it balanced, did it make a significant difference?

Post by: dogger315 on April 10, 2012, 02:19:28 PM

powerband. It brought the vibration level down to 250 levels - very nice for a long trail

ride or moto practice, no more tingly hands.

The piston window is a good mod for the KX port configuaration but not so much for the

CR's. Here are a couple of pictures of my cylinder to see the difference between the two.

The big thing on the CR is to relieve the exhaust port bridge and add some oiling holes to

the front of the piston.

I think the 41mm PWK will be more than enough for your application. I started with a 39.5

(the KX OE) and switched down to a 38 for better low to mid and throttle response for MX.

dogger

Post by: Twostrokepower!!! on April 11, 2012, 03:35:11 AM

Post by: Mike D on April 11, 2012, 03:15:04 PM

That is hands down the sexiest motor ive ever seen...

Wait till he posts the pics of it in the bike, probably the nicest 500 I've ever seen.

Post by: Marco810 on April 13, 2012, 07:39:02 PM

Sealed up a potential leak area, not sure why kawi machined through the cases to insert the bearing housing. Another great tip from kxriders, I take no credit for most of the mods ill be doing to this engine

Post by: cnrcpla on April 13, 2012, 10:50:07 PM

Works better than duct tape

Works better than duct tape

Post by: Marco810 on April 13, 2012, 11:01:32 PM

Post by: Marco810 on April 20, 2012, 08:20:03 PM

)

)

Post by: Recovered on April 21, 2012, 02:51:51 AM

stand within an ear shot of the oven. When you hear a "clank", the bearing is out.

Ask Charles.

Post by: TotalNZ on April 21, 2012, 07:02:23 AM

put them in an oven with the bearings facing down at 400 degrees.thats how i do mine, works every time no need for a hammer.

stand within an ear shot of the oven. When you hear a "clank", the bearing is out.

Ask Charles.

Post by: Marco810 on April 21, 2012, 02:24:00 PM

Post by: Marco810 on April 24, 2012, 01:57:03 AM

Crankshaft and 01 250 ignition is on its way, thinking about getting a hpi programmable cdi down the road. No idea on the eta on my jug, may call Eric if i find time this week

Post by: Marco810 on April 28, 2012, 07:20:51 PM

Eric is just "finishing up the head milling", should see my cylinder soon

. Havent even ordered my piston yet... or carb... or..

. Havent even ordered my piston yet... or carb... or..

Post by: Marco810 on May 02, 2012, 03:02:56 AM

Post by: Marco810 on May 04, 2012, 03:26:56 PM

Post by: Marco810 on May 06, 2012, 02:33:40 AM

Post by: cnrcpla on May 06, 2012, 03:18:54 AM

Post by: Marco810 on May 06, 2012, 04:11:15 AM

also a case splitter is a must, never hit the crank with anything, just putting it out there

Post by: Marco810 on May 07, 2012, 02:53:36 AM

hard to tell if he did any work, but i do notice a few small changes

hard to tell if he did any work, but i do notice a few small changes

Post by: cnrcpla on May 07, 2012, 03:04:25 AM

Post by: scotty dog on May 07, 2012, 06:23:22 AM

Post by: Marco810 on May 07, 2012, 02:42:43 PM

Post by: eprovenzano on May 07, 2012, 05:51:44 PM

Well i made some measurements and the ports havent been touched with tooling, just a little grinding to sharpen the bridges. I'm not impressed at all and at this point it kinda derailed my build, just going to have to run it like it is till i decide to actually get it ported. Needless to say i wont be dealing with eric againIf the workmanship is not what you wanted, I'd be on the phone getting it straighted out.

Post by: Marco810 on May 07, 2012, 09:14:34 PM

Post by: dogger315 on May 07, 2012, 09:46:32 PM

Quote

Needless to say i wont be dealing with eric againJust curious which port package you specified; more low, more high, "mo betta"?

EG did the Mo betta on my 500 and there was a great deal of work done. I

wonder if there was some mis-communication or something. I would definitely

call and talk to him about this.

Quote

I have never split cases before, but when you do that, do you just line up the gear configuration with the bearings and all that stuff and put it together?I have a slightly different approach. Like Marco said, you want to put everything in the right

side case. I place the case on my homemade engine stand (see picture) and put the main

and countershaft clusters in meshed together. Then install the shift forks, shift drum and

shift fork shafts in that order. Then I install the left side case. This is a test fit to check

that the tranny spins freely and is done before the crankshaft goes in.

Once I make sure the gear clusters are assembled correctly (the reason for the test fit), I take

it all apart and do it again, only this time I start with the crankshaft which I install with an

installation tool that draws it into the crank bearing.

Just another technique to assemble a bottom end.

dogger

Post by: Marco810 on May 08, 2012, 02:52:34 AM

QuoteNeedless to say i wont be dealing with eric againJust curious which port package you specified; more low, more high, "mo betta"?

EG did the Mo betta on my 500 and there was a great deal of work done. I

wonder if there was some mis-communication or something. I would definitely

call and talk to him about this.QuoteI have never split cases before, but when you do that, do you just line up the gear configuration with the bearings and all that stuff and put it together?I have a slightly different approach. Like Marco said, you want to put everything in the left

side case. I place the case on my homemade engine stand (see picture) and put the main

and countershaft clusters in meshed together. Then install the shift forks, shift drum and

shift fork shafts in that order. Then I install the right side case. This is a test fit to check

that the tranny spins freely and is done before the crankshaft goes in.

Once I make sure the gear clusters are assembled correctly (the reason for the test fit), I take

it all apart and do it again, only this time I start with the crankshaft which I install with an

installation tool that draws it into the crank bearing.

Just another technique to assemble a bottom end.

dogger

I checked the topend port box on the form, and got charged for that service, even is printed "porting work" on my recipe. being a topend job i should be seeing some significant duration changes, how ever this is a stock port config.

Im not trying to bad talk Eric Gorr or anything, but i feel like i got shafted. Im busy with work this week but when i get time ill see what he has to say

Post by: dogger315 on May 08, 2012, 03:28:13 AM

Quote

Im not trying to bad talk Eric Gorr or anything, but i feel like i got shaftedLooking at the pictures, I totally agree. Visually, the difference between the OE cylinder and

what I got back from EG was night and day. It'll be interesting to here what is said when

you call. I just hope you get it worked out and get the "fire breathing" cylinder you want.

dogger

Post by: cnrcpla on May 08, 2012, 12:10:57 PM

That's going to be a bit of a monster

That's going to be a bit of a monster

Post by: 2T Institute on May 08, 2012, 01:08:39 PM

Got my cylinder backhard to tell if he did any work, but i do notice a few small changes

Well i made some measurements and the ports havent been touched with tooling, just a little grinding to sharpen the bridges. I'm not impressed at all and at this point it kinda derailed my build, just going to have to run it like it is till i decide to actually get it ported. Needless to say i wont be dealing with eric again

You have every right to be angry Marco. I would be demanding your money back.

Post by: eprovenzano on May 08, 2012, 01:50:00 PM

Please keep us updated

Post by: Recovered on May 08, 2012, 02:39:32 PM

I have to ask; why do you want porting done on a 500?That's going to be a bit of a monster

Some people can uncork them, man. And sometimes port work is just to clean up casting flaws (these things are sand cast, i believe) which can smooth out the delivery.

Well, let me take this opportunity to share my EG story as I just got off the phone with him.

He has had my jug for a month. He does not have possession of it, and does not know when he will. I am left at "you'll get it when you get it."

This is a FAR CRY from the guys who claim to have sent it to him on Saturday and got it back 6 days later on the following Friday. Like I said in my thread, the best port work in the world is nothing if the jug isn't on the bike.

Post by: dbf498 on May 08, 2012, 11:53:01 PM

To be honest, I've been really pleased with the work he's done on my stuff even if at times it takes a little longer to get it back. Nowadays the number of shops that specialize in 2T work seems to be getting smaller; since the big money is in repairing ticking time bombs. Patience has become my new mantra as the older I get I realize I have less of it left.

I'm in a similar situation as I sent a crank off to crank works for balance and it's been going two months. The crank, along with all the bits and pieces, was finally shipped to my son's house last Thursay; UPS will not deliver to an APO address. So now I'm at the mercy of the USPS and hoping like mad they don't pull an Ace Ventura on it, I've had boxes come in that no longer looked like boxes. I'm also waiting on a top end from EG but it's a spare and I'm not in as big a rush for it; although I'd still like to have it in my hot little hands all the same.

Post by: Marco810 on May 09, 2012, 03:49:53 PM

Old rings

New rings. Feeler gauge doesnt even go that high

Post by: 2T Institute on May 10, 2012, 03:43:56 AM

Post by: Recovered on May 10, 2012, 03:49:40 AM

Post by: Marco810 on May 10, 2012, 05:16:12 AM

Have you checked the piston to bore clearence ?

Only have a caliper and odered a bore gauge off ebay, .01" was what i got

topend is way out of spec, bore looks to be good though

Post by: xandyx on May 12, 2012, 02:11:43 PM

Post by: 91kx500 on January 13, 2013, 11:07:25 PM

Quoteporting, 250 ignition, 41mm pwk (pump gas), and what ever else i can think ofI recently built a CR500 engine specifically for MX so our two goals are miles apart, but some

of the mods I made would be beneficial for a dune bike. For the top end, I had Eric Gorr do the

port and head work. He recommended a Wiseco piston because it is more durable than the

cast OE. I sent that piston and crank assembly to Crank Works for balancing at 6-8000 rpm

which is the meat of the powerband for a 500. I also had all of the rotational internals REMed.

This process greatly reduces friction and heat and improves clutch action and shifting. I also

installed a VForce 3 reed and a 2000 CR250 ignition with a Vortex IC. IMO, all of these changes

would also be beneficial to a big power, top end engine.

Here's a couple of pictures of my engine. I look forward to following your build and to see what

you ultimately come up with.QuoteWith the lighter weight that monster is going to hit like a beastActually, the bulk of the weight (crankshaft), is still there. The smaller rotor helps with the gyro

effect and makes the bike feel lighter and more manageable in the air and in corners. The biggest

gain is going from an analog to a digital ignition and the ability to program the mapping. You can

really increase the hit (if you're a sadist), or virtually eliminate it.

dogger

I see you have the Delta 3 reed valve system. Did that come with a boot that goes to your carb or do you have to use the stock boot?