Post by: dogger315 on June 25, 2011, 04:23:59 PM

I gave up on the back ordered Pro Circuit linkage and decided to go with

an OE assembly for now. Everything is going together pretty good so far.

Here are some more pictures.

dogger

(http://i246.photobucket.com/albums/gg107/dogger315/CR500AF019a.jpg)

(http://i246.photobucket.com/albums/gg107/dogger315/CR500AF040.jpg)

(http://i246.photobucket.com/albums/gg107/dogger315/CR500AF023.jpg)

(http://i246.photobucket.com/albums/gg107/dogger315/CR500AF028.jpg)

Post by: keeptwostrokesalive on June 25, 2011, 06:29:53 PM

Post by: SachsGS on June 25, 2011, 09:05:32 PM

Post by: ACMX on June 25, 2011, 11:09:50 PM

Post by: ford832 on June 26, 2011, 04:14:43 AM

Post by: Coop on June 26, 2011, 07:20:28 AM

Post by: 2smoker on June 26, 2011, 12:10:02 PM

Post by: dogger315 on June 26, 2011, 12:58:00 PM

Quote

What issues have you run in to,or expect to have to deal with?Aside from the known problems of stuffing a CR500 engine into a CRF250 frame

which are all known and dealt with during the frame modifications, it looks like I

am going to have a clearance problem between the shock spring and the engine

case and between the airbox boot and the shock spring.

Both of these problems are caused by the titanium shock spring. The spring has

fewer coils than steel but each coil is larger in diameter and the overall diameter

of the spring is about 5mm more than a steel spring - just enough to foul the

case and boot. Of course the easiest fix would be to swap in a steel spring, but

I'm not ready to take the easy way out just yet. I can fix the airbox boot/spring

problem by removing the 10mm spacer I installed between the VForce and the

cylinder to boost low end. I don't have a solution I like for the case/spring yet.

That's the challenge with these projects, and half the fun. I'll keep you posted.

dogger

Post by: JohnN on June 26, 2011, 04:02:39 PM

Your bikes always have that factory bike look and feel to them, with everything looking absolutely new and original. Awesome job on this one.

What's the deal with the suspension? It looks like it's a couple of grades higher than the standard bikes have on them...

How bad is the rear spring to case overlap? Even from the photos about it looks like it will hit. Can't wait to see the way you solve it.

Looking forward to more photos.

Post by: scotty dog on June 26, 2011, 06:30:11 PM

Post by: dogger315 on June 27, 2011, 07:08:03 AM

to go all out. My goal is to build a bike similar to what team Honda would field if the open class

was still around, so I am using every trick part I can find.

Quote

What's the deal with the suspension? It looks like it's a couple of grades higher than the standard bikes have on themGood eye John, the suspension is Pro Circuit's Works Showas.

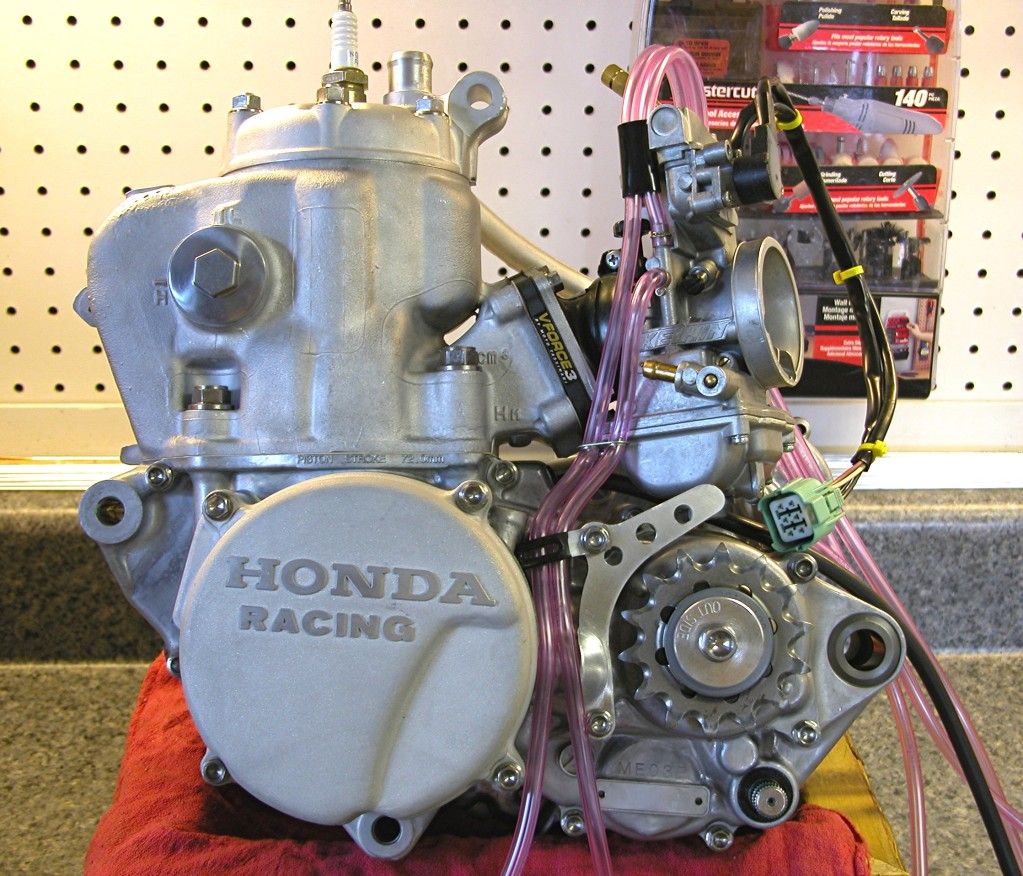

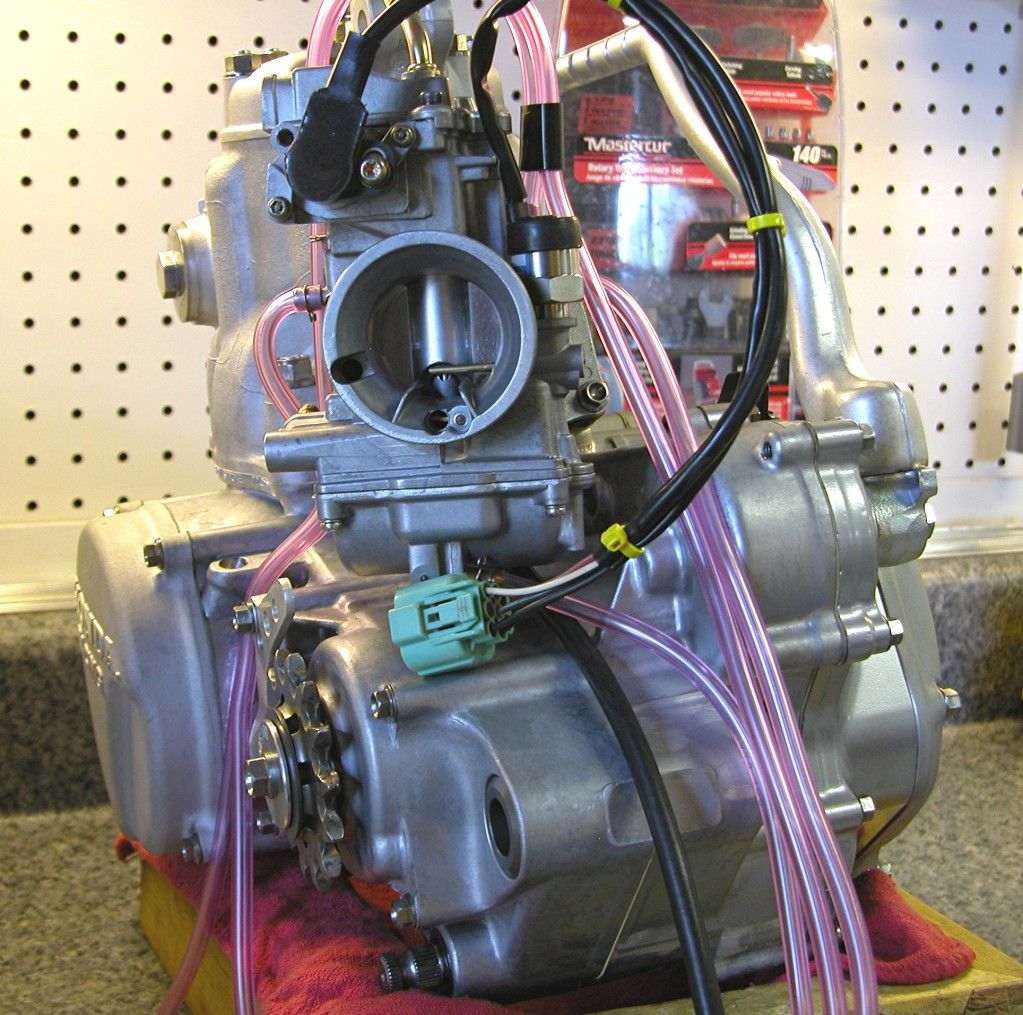

What you can't see is how "stout" the engine is. I built it from all new parts based on the 2001.

The transmission is a rare HGA close ratio unit, all the rotational and frictional surfaces have had

an REM Isotropic slick/hard coating applied. The crankshaft has been balanced, Hinson clutch,

multi map programmable CR250 ignition, Eric Gorr top end, VForce 3, Keihin 39.5mm PWK carb and

a Pro Circuit pipe and silencer. It should yield approximately 65-70 "rider friendly" hp at the CS -

way more than most mortals can use, but what a hoot to have on tap ;D

The lessons learned from this build will help with my next project: A CR250 hybrid using an equally

trick 2001 CR250 engine and a 2010-11 CRF250 frame. The engine build has already begun.

dogger

Post by: EJ on June 27, 2011, 08:15:16 AM

Good luck, and have fun with those lovely bikes you build!

Post by: sticky throttle on October 27, 2012, 03:30:32 PM

Thanks guys.QuoteWhat issues have you run in to,or expect to have to deal with?Aside from the known problems of stuffing a CR500 engine into a CRF250 frame

which are all known and dealt with during the frame modifications, it looks like I

am going to have a clearance problem between the shock spring and the engine

case and between the airbox boot and the shock spring.

Both of these problems are caused by the titanium shock spring. The spring has

fewer coils than steel but each coil is larger in diameter and the overall diameter

of the spring is about 5mm more than a steel spring - just enough to foul the

case and boot. Of course the easiest fix would be to swap in a steel spring, but

I'm not ready to take the easy way out just yet. I can fix the airbox boot/spring

problem by removing the 10mm spacer I installed between the VForce and the

cylinder to boost low end. I don't have a solution I like for the case/spring yet.

That's the challenge with these projects, and half the fun. I'll keep you posted.

dogger

Dogger, great build, What solutions did you come up with to run the ti. spring? I'm having the same problem with a steel spring at 5.4 spring rate. Your help would be greatly appreciated.

Post by: dogger315 on October 27, 2012, 08:18:32 PM

steel spring. Even with that, I had to radius the case. To do that, use a grinding disc the same

OD as the spring and run it off the center line of the case, I took off 2mm. Remember, that

part of the case is not part of the transmission seal, just surrounds the swingarm pivot bolt

passage. After grinding, hit it with 320 then 400 grit wet sandpaper and finish with WD40

and a Grey or Green Scothbrite pad to return the surface back to normal.

Here's a picture:

dogger

Post by: dean100yz on October 27, 2012, 08:44:22 PM

Im in love with this! My dad & me are the same, will always get things as original or perfect as possible.

Looks like you have an amazing piece of work there. Thats gotta be pulling 55+ at the rear minimum

Post by: sticky throttle on October 27, 2012, 09:42:17 PM

I ended up finding a Ti spring from a different manufacturer (RCS), that had the same OD as aOk I see what you've done. I'm in the same boat. I 'm thinking of possibly making a longer link, about 2mm, but then I need to mess with dropping the forks and or offset clamps.

steel spring. Even with that, I had to radius the case. To do that, use a grinding disc the same

OD as the spring and run it off the center line of the case, I took off 2mm. Remember, that

part of the case is not part of the transmission seal, just surrounds the swingarm pivot bolt

passage. After grinding, hit it with 320 then 400 grit wet sandpaper and finish with WD40

and a Grey or Green Scothbrite pad to return the surface back to normal.

Here's a picture:

dogger

I like the idea of coping the case because I dint have to mess with anything and still have a lot more adjustably for chassis set up. How much meat is in the case at that area where you coped it? I'll look at the parts to try and figure it out.

Post by: GlennC on October 28, 2012, 06:58:07 PM

Is this the build that is posted on the cr500riders site?

if so are you still doing a CR250 conversion in the near future?

I am considering puting a 2001 CR250 engine into a 2004 CRF250R frame, I was looking for some advise with the project.

GlennC

Post by: dogger315 on October 29, 2012, 01:20:11 AM

Quote

Looks like you have an amazing piece of work there. Thats gotta be pulling 55+ at the rear minimumThanks a bunch! Don't know what it's producing at the rear wheel, but it's enough to put a big

grin on your face.

Quote

I 'm thinking of possibly making a longer link, about 2mm, but then I need to mess with dropping the forks and or offset clamps.Unfortunately, changing the length of the pull rods will not move the shock further from the case. Because the dogbone position is fixed, longer

pullrods will only rotate the dogbone counter clockwise. All this will get you is a change in the vertical axis for the shock (lower your seat height).

Quote

How much meat is in the case at that area where you coped it?There is about 5mm. Here's a picture:

My Ti shock spring is rated at 5.3kg/m. It's the same diameter as a 5.8 kg/m steel spring.

Radiusing the case should work as well for your bike.

Quote

Is this the build that is posted on the cr500riders site?Yes, it's the same bike. I'm working on that CR250 project right now.

if so are you still doing a CR250 conversion in the near future?

I am using a 2009 CRF 250R frame and adding a copy of a 2007 CR250 cradle.

I'm taking this conversion up a few notches. I used a handheld laser scanner

to scan the 07 and 09 frames and the 00 CR250 engine. The plan is to do all

the design work using CAD (SolidWorks), then produce the new cradle rails

and engine mounts with CAM. After a lot of digging, I finally sourced the radiused

corner square metric tubing that Honda uses for the cradle. The engine mounts

will be reproductions of the OE Honda mounts using 6061 Aluminum stock. I'm

using the hoop from an 07 CR250 donor frame, but the CRF hoop will work just

as good.

This conversion is proving to be much more difficult than the 500, partly because

of my insistence on no billet frame members, and partly because the CR250 engine

shape is more difficult to adapt.

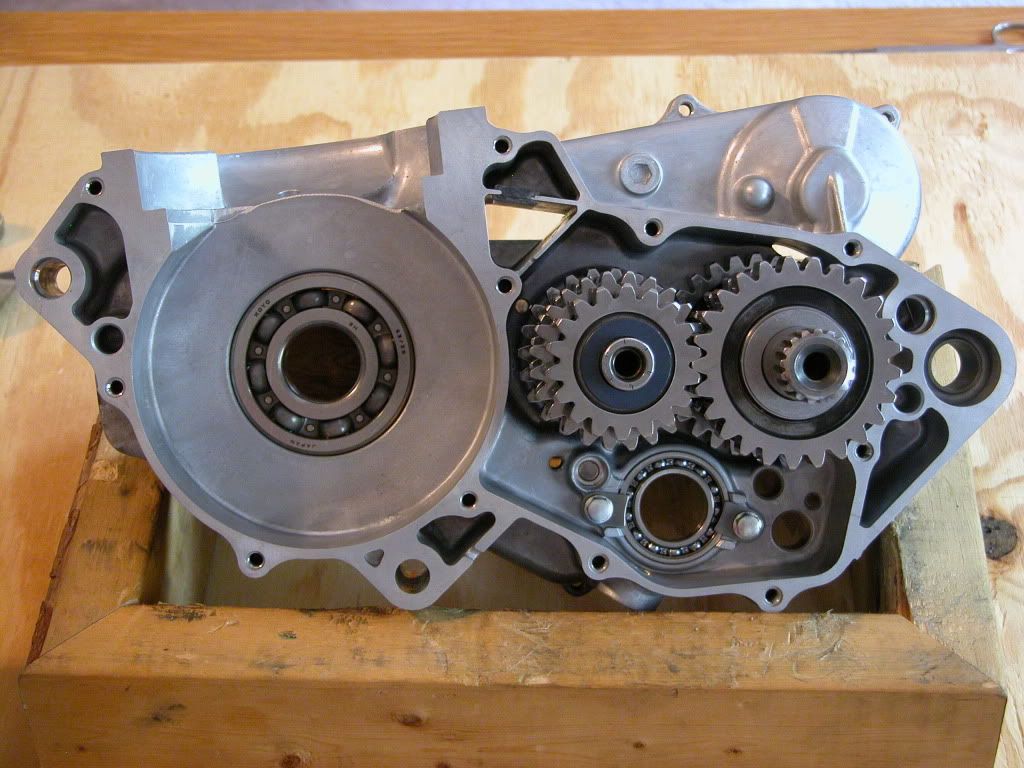

Here's a couple of pictures of the 00 CR250 engine I built for the bike:

If you have any questions, PM me. I'll be happy to fill you in.

dogger

Post by: sticky throttle on October 29, 2012, 05:38:33 AM

I'm still going to make a few calls tomorrow and see if I can find a smaller diameter spring at the same spring rate

and provide more clearance, even with it coped.

Thanks again!

Post by: SachsGS on October 29, 2012, 03:52:16 PM

I recall reading in DB magazine about a 2000/1 CR250 AF conversion, who did that one?

Post by: Lolerbabop on October 29, 2012, 04:02:42 PM

Post by: dogger315 on October 29, 2012, 08:07:04 PM

Quote

Aren't the Honda frames a 7000 series self hardening alloy whereas the 6061 you would normally treat to T6?Yes, Honda uses 7075-0 Alloy for the frame rails and extrusions and 6061-T6 for the various brackets and engine mounts.

The "0" state for the 7075 results in a tensile strength of 40,000 psi. The "T6" state for the 6061 yields a tensile strength

of 42,000 psi. That's the exact same combination I'm using. The goal is to maintain the same strength and flex to preserve

the OE chassis dynamics. That's not the case when you replace a tube cradle with a solid billet piece.

Quote

I recall reading in DB magazine about a 2000/1 CR250 AF conversion, who did that one?Not familiar with that test since the 2000/01 CR250s were already "AFs".

Quote

Will you try out the SmartCarb?I may try one down the road. Right now, I'm using a PWK S with TPS and a power jet. The carb electrics will be run

with a Vortex digital, programmable IC.

This engine is a carbon copy of the engines TMR built for me back in 2000-01. Those engine produced mid 50s

hp on VP MR2. MR2 is no longer being produced so I switched to Renegade SX2. The SX2 is a close copy of MR2,

so I'm expecting similar results. 54-56 hp in a bike that should have a dry weight under 200 lbs - If the smartcarb

claims are true, mounting one would be complete overkill on a bike like this.

dogger

Post by: citabjockey on October 29, 2012, 08:34:45 PM

But I love it! Just have to find someone that can ride it to its full potential and then go to Monster Cup and take home $1M

54-56 hp in a bike that should have a dry weight under 200 lbs - If the smartcarb

claims are true, mounting one would be complete overkill on a bike like this.

dogger

Post by: gpnewhouse7 on October 29, 2012, 09:18:19 PM

I'm just curious because the new KTMs only make 51hp and KTM have always been known for having the most powerful motors.

Apart from that I'd just like to say great work on the 250 and 500.

Post by: dogger315 on October 29, 2012, 11:23:26 PM

Quote

just wondering where you get the 54-56hp claim from?Those claims come from dyno runs performed by Tom Morgan back in the

day. This engine is a copy of the engines he built for Heath Voss and Co.,

when they were riding for Blackfoot Honda. The dyno numbers were in the

53-55 hp range on race gas. I have added oxygenated race gas (not legal

in AMA pro racing), which is good for 1 to 2 additional hp, so I'm upping the

number to 54-56 hp.

Quote

the new KTMs only make 51hpOnly

, That's a big number from a stock production engine The stock 00-01

, That's a big number from a stock production engine The stock 00-01 CR250 engine only produced 47 hp in comparison and it was the king of the hill

at the time. FWIW, it cost me almost as much as a new 250SX to build this

engine, but like my 500, it isn't a budget build. Adding horsepower and

reliability doesn't come cheap. Besides, what's the point of going through all

the trouble of building a two stroke conversion that's down 5 hp to the

competition? The goal is to produce the fastest, lightest and the best handling

and suspended 250 two stroke on the track - whatever it takes or cost.

dogger

Post by: gpnewhouse7 on October 30, 2012, 09:04:13 AM

And I put ?only? 51hp for the KTM because its had 12 more years of development not because 51hp isn't a lot.

Post by: SachsGS on October 30, 2012, 03:17:04 PM

Post by: dogger315 on October 30, 2012, 03:45:53 PM

Quote

Is that the Blackfoot Honda out of Calgary, Alberta?Yes it is. They had a good, well funded satellite team with some

talented riders and a back door deal with Factory Honda for some

"works" parts. TMR built the engines for them and those engines

were reportedly very close to the Team Honda engines according

to riders that had the opportunity to ride both.

Quote

because its had 12 more years of developmentInteresting thought. I remember talking to some of the folks at

Honda about this same subject years ago. They said at the time,

the current design piston port engine had been developed about

as far as it could be. Some of the engine builders I worked with

said the same thing.

I am always bagging on Honda for ruining the CRs with the case

reed engine, but it may have been a case where funds and R&D

were being diverted to the fledgling four stroke program and the

case reed design never got a chance.

If all of the R&D Honda normally put into an engine had been

devoted, the "RC" may have developed into another big power

arm stretcher like so many of it's predecessors instead of the

last place bike stinking up all the shootouts.

dogger